Technical Research. Information Artchitecture

User Research · Information Architecture

MARKO, Minimize the Communication Gap

Overview

Features

Research

Iteration

INTRODUCTION

MarkO is a collaboration system that allows the footwear designers to 3D scan their samples and marks their annotation easily.

TEAM

Feather Xu

Rhema Gabriela

Carina Geng

MY ROLE

Project Manager

User Research

UI Design

Information Architecture

TIMELINE

Jan 2021- May 2021

Week 1-8: Research & Analysis

Week 9-14: Design & User Testing

Context

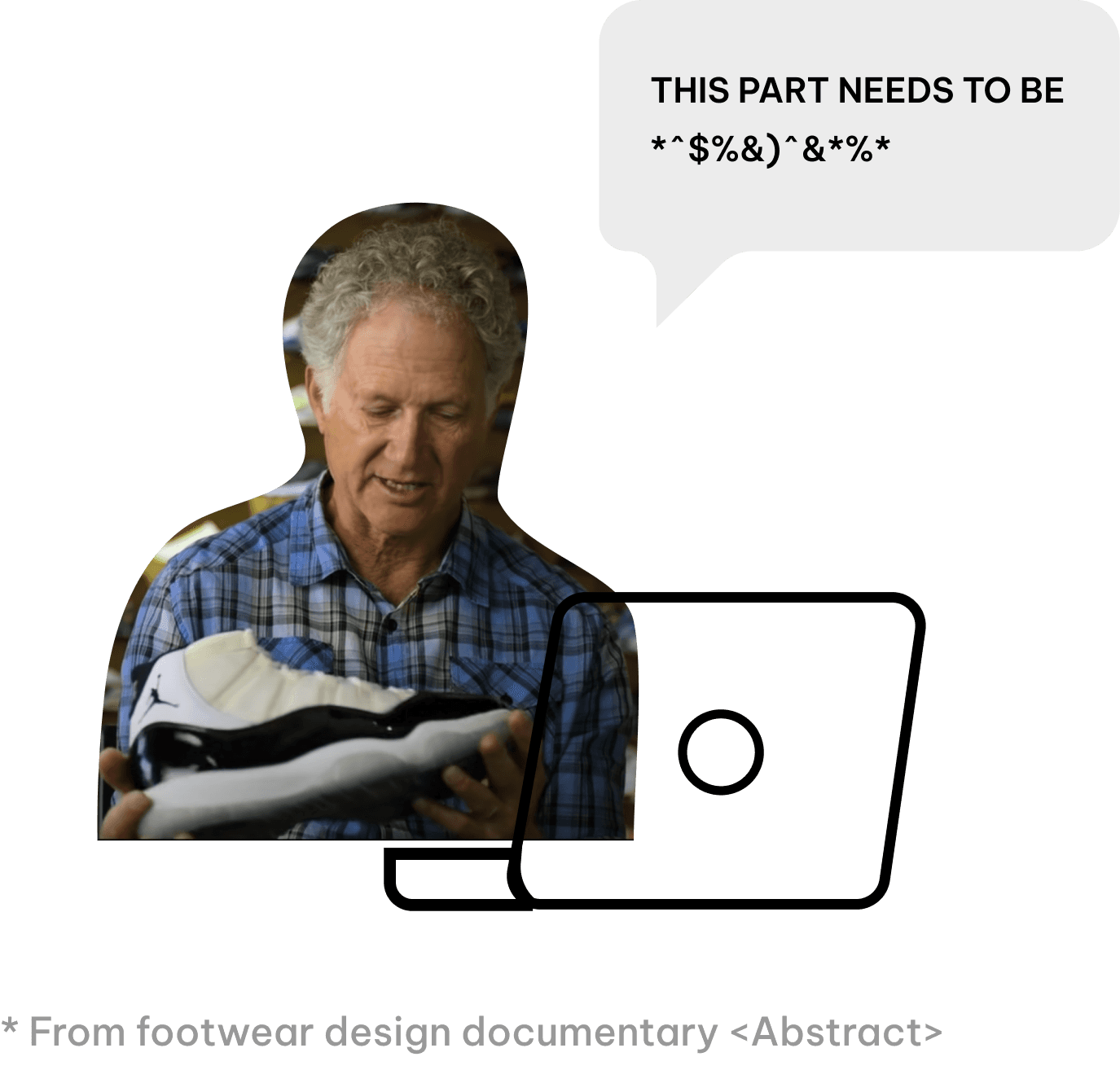

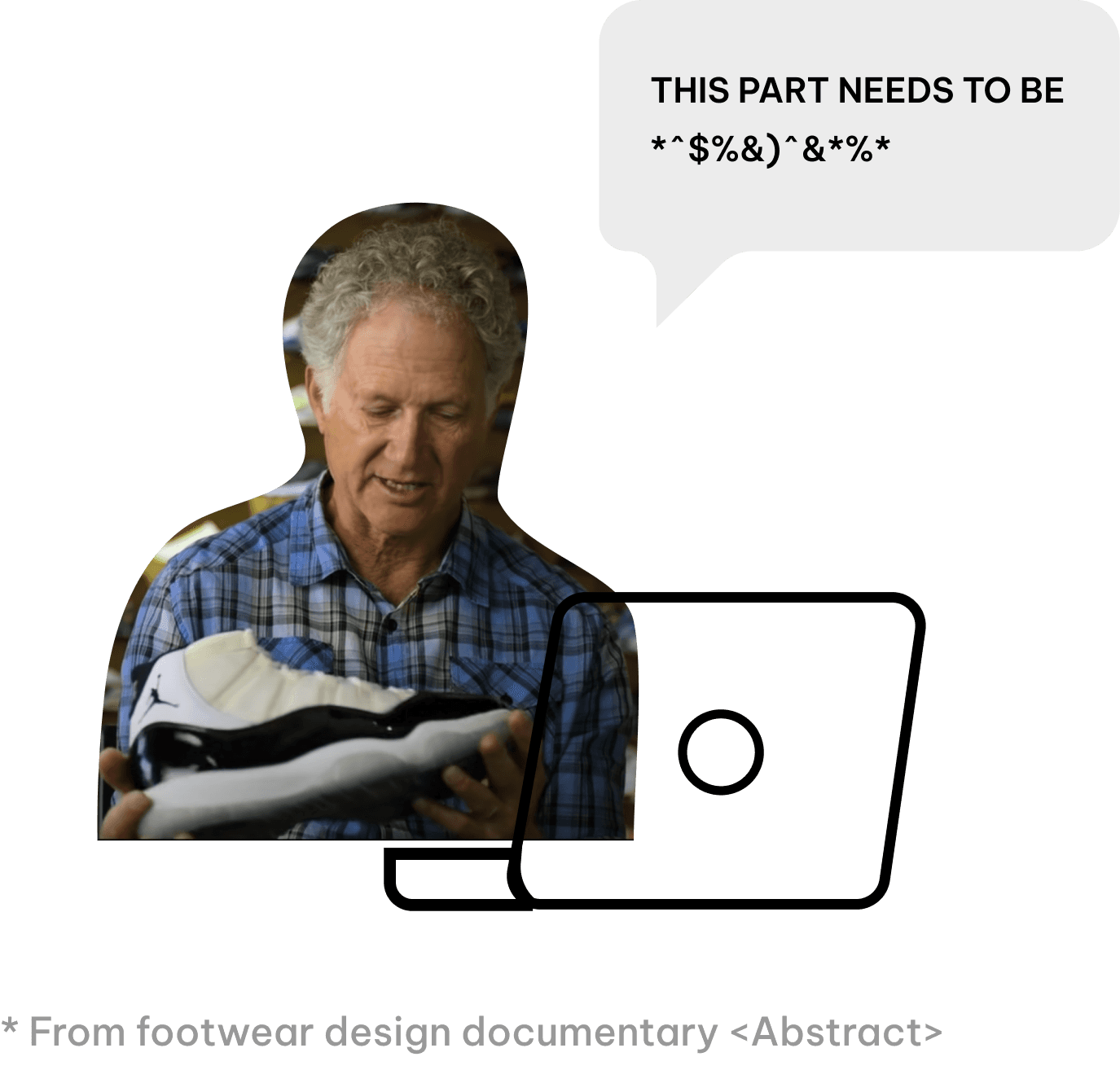

While everything moved to remote during Covid, sample revision for footwear designers and engineers are getting harder without in person interaction and physical sample.

Footwear designers needs to validate samples with developers constantly in the design process to make the product iterate efficiently for a better delieverable/launch.

Technical Research. Information Artchitecture

User Research · Information Architecture

MARKO, Minimize the Communication Gap

Overview

Features

Research

Iteration

INTRODUCTION

MarkO is a collaboration system that allows the footwear designers to 3D scan their samples and marks their annotation easily.

TEAM

Feather Xu

Rhema Gabriela

Carina Geng

MY ROLE

Project Manager

User Research

UI Design

Information Architecture

TIMELINE

Jan 2021- May 2021

Week 1-8: Research & Analysis

Week 9-14: Design & User Testing

Context

While everything moved to remote during Covid, sample revision for footwear designers and engineers are getting harder without in person interaction and physical sample.

Footwear designers needs to validate samples with developers constantly in the design process to make the product iterate efficiently for a better delieverable/launch.

Technical Research. Information Artchitecture

User Research · Information Architecture

MARKO, Minimize the Communication Gap

Overview

Features

Research

Iteration

INTRODUCTION

MarkO is a collaboration system that allows the footwear designers to 3D scan their samples and marks their annotation easily.

TEAM

Feather Xu

Rhema Gabriela

Carina Geng

MY ROLE

Project Manager

User Research

UI Design

Information Architecture

TIMELINE

Jan 2021- May 2021

Week 1-8: Research & Analysis

Week 9-14: Design & User Testing

Context

While everything moved to remote during Covid, sample revision for footwear designers and engineers are getting harder without in person interaction and physical sample.

Footwear designers needs to validate samples with developers constantly in the design process to make the product iterate efficiently for a better delieverable/launch.

We are now facing the challenge of

How do we minimize the communication gap between designers and developers to avoid redundant work and wasted time on back and forth.

Skip to Design

8

Stakeholder Interview

16

User Interview

Start with research

Our Challenges

As a digital UX Designer, we had no idea about how industrial designer, specifically footwear designer works and collaborate with their engineers.

Our Questions

Here are a list of things we need to figure out through research:

1/ What is their workflow?

2/ How do they collaborate while WFH?

3/ How does WFH affected their working dynamic?

In order to figure these out, we scheduled 1-1 interview with 8 stakeholders and 16 interviewees to find out what is lacking in the current situation the most. And here is what we found.

Extended Work Flow

1.

Espeically with developers

Before

In Person Sample Revision

According to our interviewee, when everyone were in the same office, they could easily go to each other’s table, communicate their ideas visually.

01. Receive sample

02. Find out issues

03. Discuss with developer

04. Make Revisions

Current - WFH

Remote Sample Revision

While working in different places or even different timezone, the designers needs to do extra annotation and documentation for clearer explanation.

01. Receive sample

02. Find out issues

03. Take pics and videos

04. Annotate the problem

05. Pin references

06. Note down dimensions

07. Schedule meeting

08. Make Revisions

"I feel it takes a longer time now to prepare what you want to talk about, that's for sure"

Mr.K, Sr footwear Desginer

Longer Discussions

2.

And why it's a problem

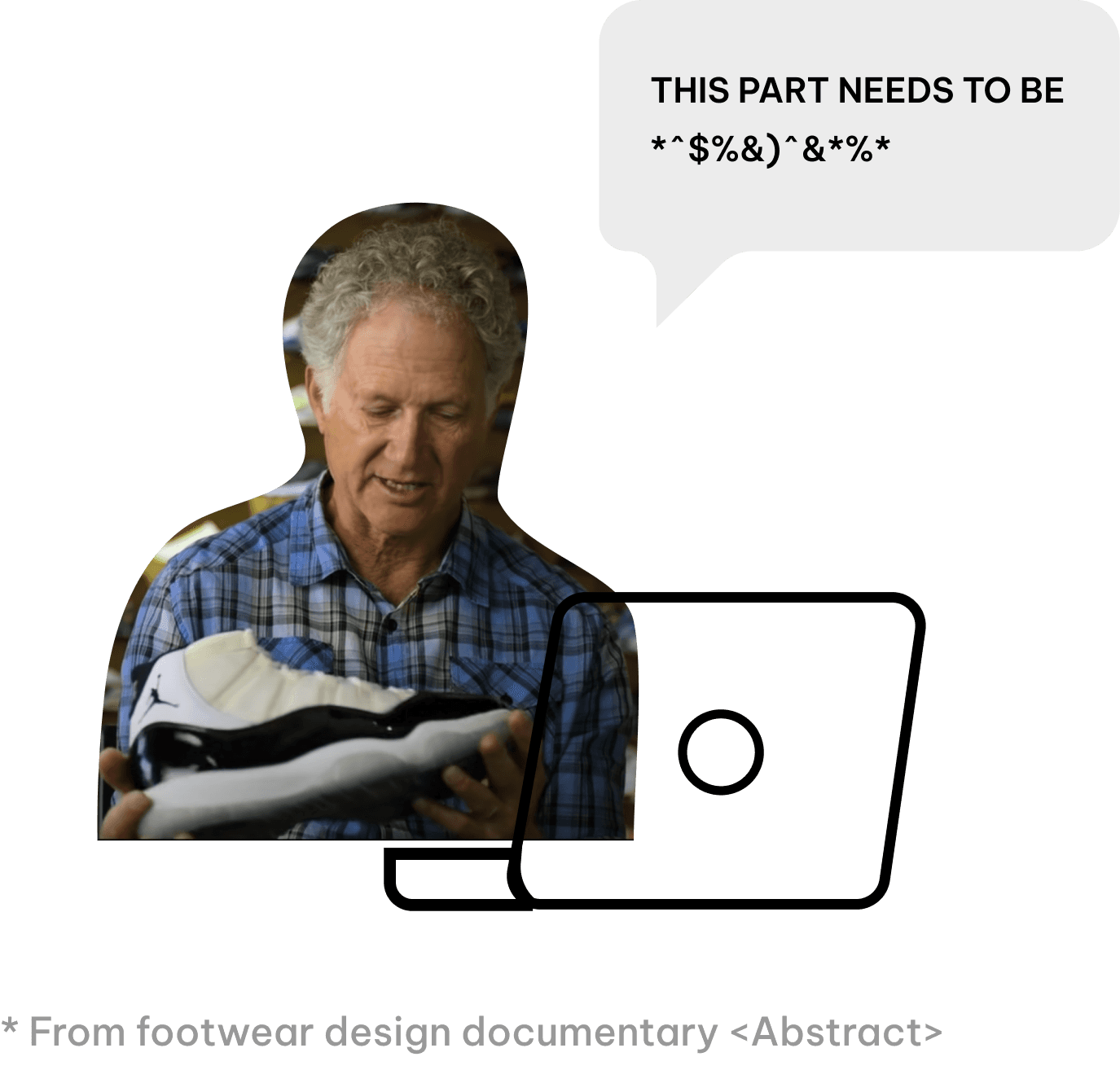

Problem 01

Sample Tangibility are Limited

Sometimes only a few team members have access to the sample, or they will only review it remotely based on the low quality video that factory sent.

This cause them missing design details and it’s hard for them to stay on the same page.

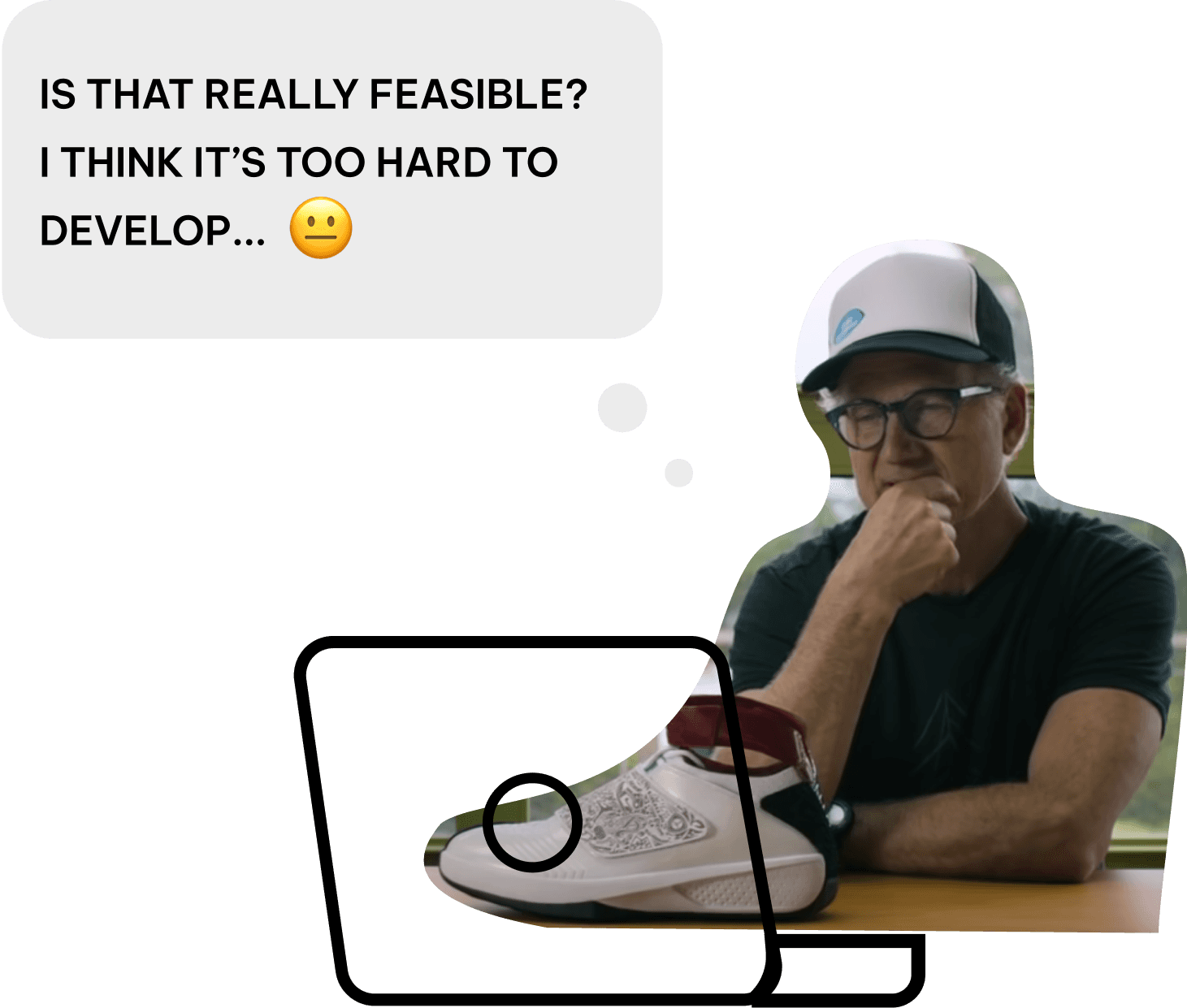

Problem 02

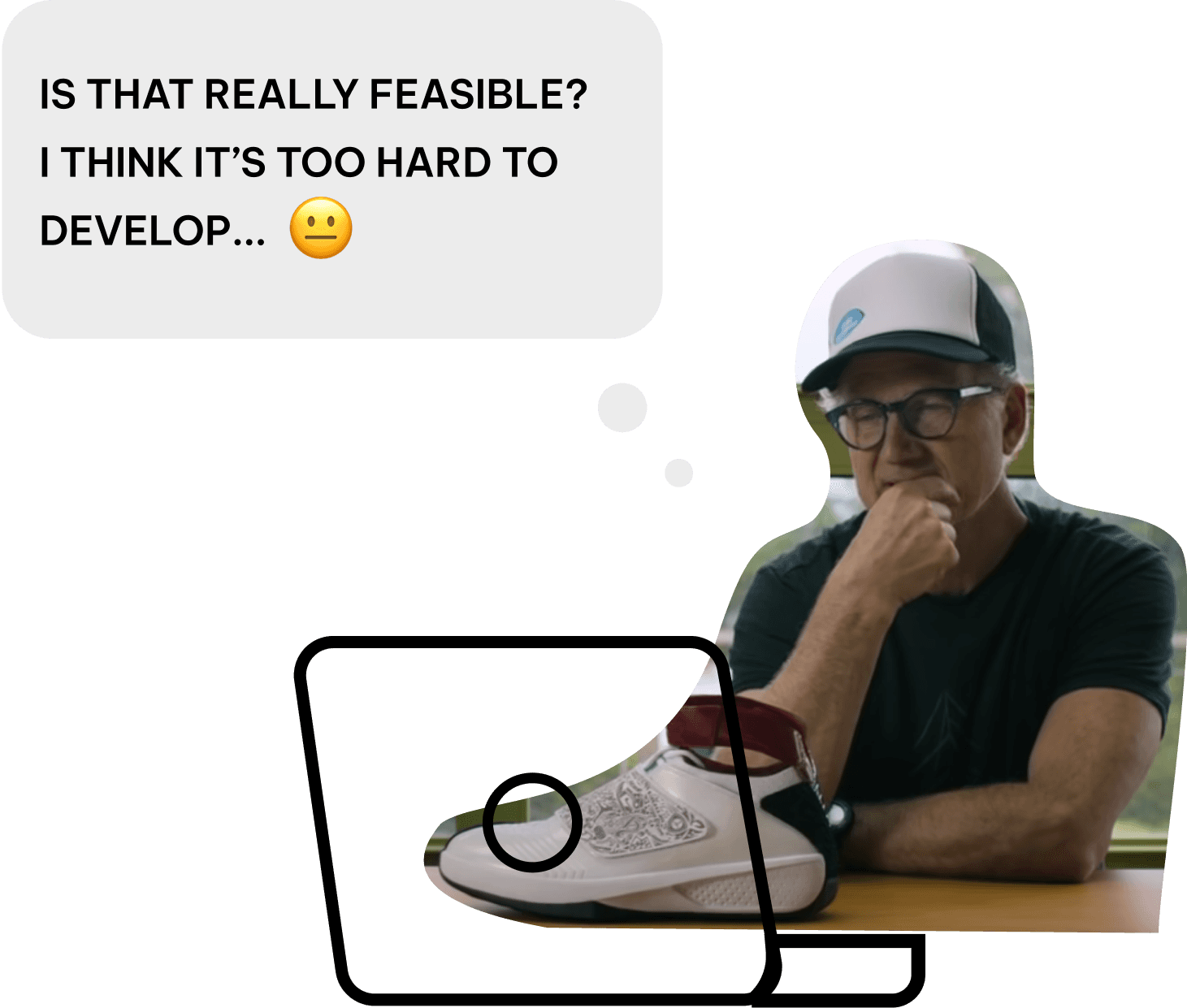

Mindset Difference Brings Inefficiency

Designers values creativity and user needs while developers focus on feasibibility and budget the most. There’s always compromise going on and extra explanation is needed to make their point through.

Problem 03

Harder to Build Trust

Withought the instant and natural feedback as in person does,any communication gap in the remote environment would be easily enlarged.

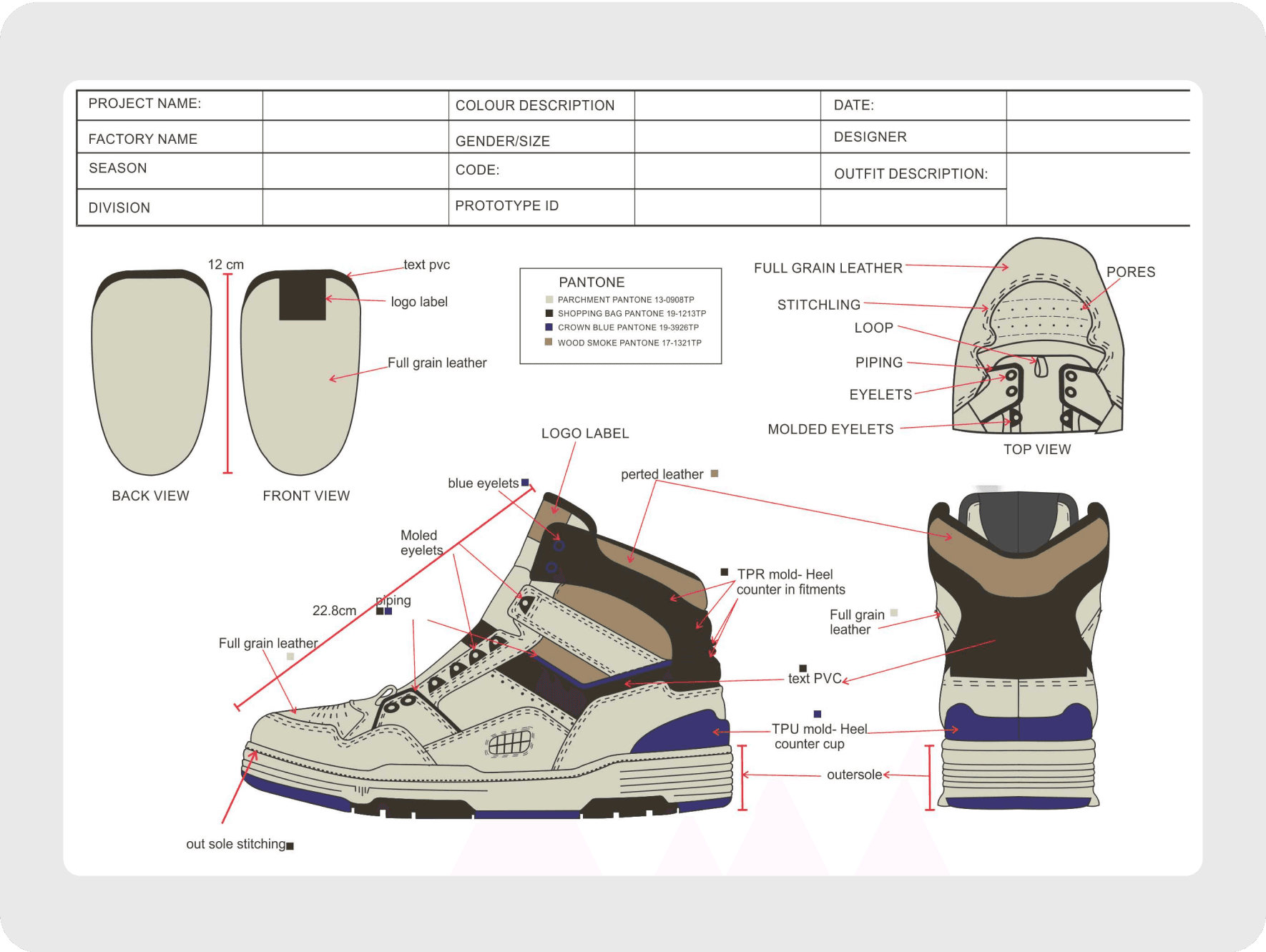

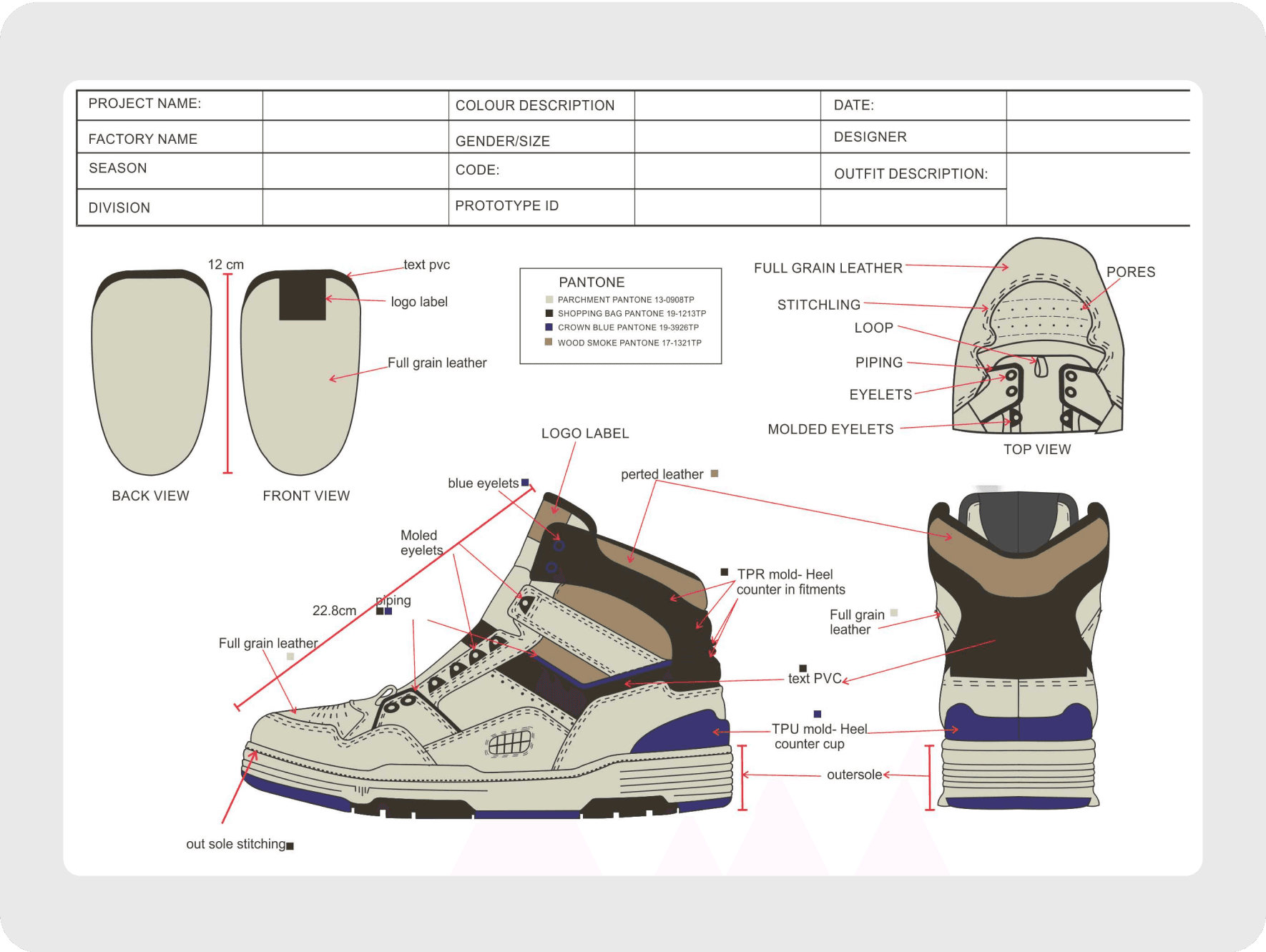

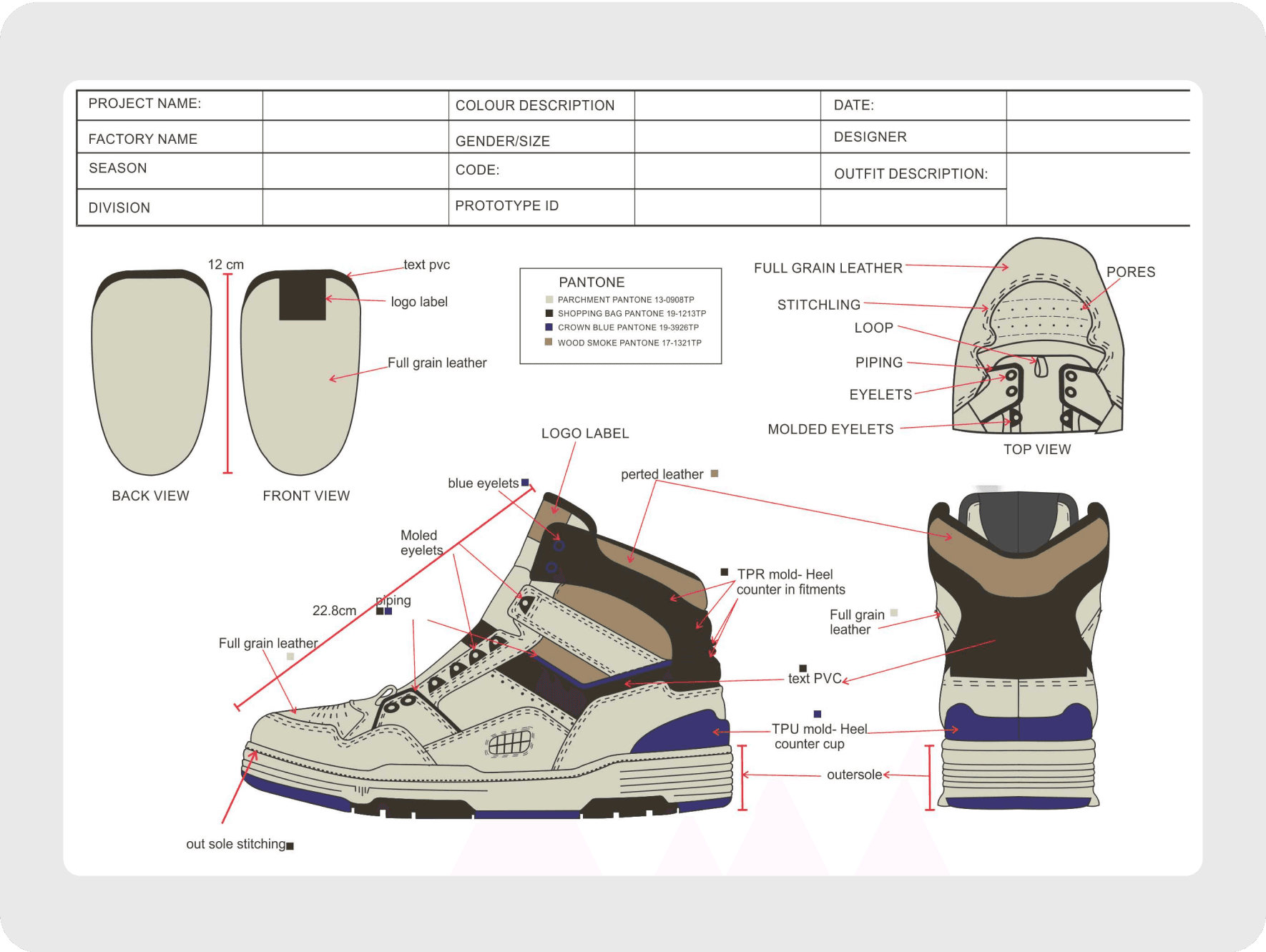

3D Workflow being more efficient nowadays

3.

And how is it hard to adapt

Current

2D Techpack Based Design

Different from other product disciplines, footwear designers design and iterate based on techpack because footwear 3D modeling needs too much extra effort and the techpack is clearer for developer and factory.

Trend

Design Review in 3D Basis

5 out of our 16 interviewees told us they tried several team review sessions in oculus as if they were meeting in person. By seeing the same model, their communication is more efficient.

However, this is hard to adapt 3D in their current workflow due to 1)budget,2)and sample developers still prefer techpack for clearer design details.

Efficiency = Quality + Time

Currently, either the work quality is sacrificed or the deadlilne would be delayed, overall efficiency is low.

In order to collaborate more efficiently, both footwear designers and developers needs:

Conclude Finding

01

Clear Interface for both roles to stay updated on project’s progress

02

Intuitive and accurate annotation tools

03

Organized and traceable revision history

04

Building Trust in the team through clearer communication

Our Goal

Make communication between designers and developer clearer so they build better trust and reduce work time.

We are now facing the challenge of

How do we minimize the communication gap between designers and developers to avoid redundant work and wasted time on back and forth.

Skip to Design

8

Stakeholder Interview

16

User Interview

Start with research

Our Challenges

As a digital UX Designer, we had no idea about how industrial designer, specifically footwear designer works and collaborate with their engineers.

Our Questions

Here are a list of things we need to figure out through research:

1/ What is their workflow?

2/ How do they collaborate while WFH?

3/ How does WFH affected their working dynamic?

In order to figure these out, we scheduled 1-1 interview with 8 stakeholders and 16 interviewees to find out what is lacking in the current situation the most. And here is what we found.

Extended Work Flow

1.

Espeically with developers

Before

In Person Sample Revision

According to our interviewee, when everyone were in the same office, they could easily go to each other’s table, communicate their ideas visually.

01. Receive sample

02. Find out issues

03. Discuss with developer

04. Make Revisions

Current - WFH

Remote Sample Revision

While working in different places or even different timezone, the designers needs to do extra annotation and documentation for clearer explanation.

01. Receive sample

02. Find out issues

03. Take pics and videos

04. Annotate the problem

05. Pin references

06. Note down dimensions

07. Schedule meeting

08. Make Revisions

"I feel it takes a longer time now to prepare what you want to talk about, that's for sure"

Mr.K, Sr footwear Desginer

Longer Discussions

2.

And why it's a problem

Problem 01

Sample Tangibility are Limited

Sometimes only a few team members have access to the sample, or they will only review it remotely based on the low quality video that factory sent.

This cause them missing design details and it’s hard for them to stay on the same page.

Problem 02

Mindset Difference Brings Inefficiency

Designers values creativity and user needs while developers focus on feasibibility and budget the most. There’s always compromise going on and extra explanation is needed to make their point through.

Problem 03

Harder to Build Trust

Withought the instant and natural feedback as in person does,any communication gap in the remote environment would be easily enlarged.

3D Workflow being more efficient nowadays

3.

And how is it hard to adapt

Current

2D Techpack Based Design

Different from other product disciplines, footwear designers design and iterate based on techpack because footwear 3D modeling needs too much extra effort and the techpack is clearer for developer and factory.

Trend

Design Review in 3D Basis

5 out of our 16 interviewees told us they tried several team review sessions in oculus as if they were meeting in person. By seeing the same model, their communication is more efficient.

However, this is hard to adapt 3D in their current workflow due to 1)budget,2)and sample developers still prefer techpack for clearer design details.

Efficiency =

Quality + Time

Currently, either the work quality is sacrificed or the deadlilne would be delayed, overall efficiency is low.

In order to collaborate more efficiently, both footwear designers and developers needs:

Conclude Finding

01

Clear Interface for both roles to stay updated on project’s progress

02

Intuitive and accurate annotation tools

03

Organized and traceable revision history

04

Building Trust in the team through clearer communication

Our Goal

Make communication between designers and developer clearer so they build better trust and reduce work time.

We are now facing the challenge of

How do we minimize the communication gap between designers and developers to avoid redundant work and wasted time on back and forth.

Skip to Design

8

Stakeholder Interview

16

User Interview

Start with research

Our Challenges

As a digital UX Designer, we had no idea about how industrial designer, specifically footwear designer works and collaborate with their engineers.

Our Questions

Here are a list of things we need to figure out through research:

1/ What is their workflow?

2/ How do they collaborate while WFH?

3/ How does WFH affected their working dynamic?

In order to figure these out, we scheduled 1-1 interview with 8 stakeholders and 16 interviewees to find out what is lacking in the current situation the most. And here is what we found.

Extended Work Flow

1.

Espeically with developers

Before

In Person Sample Revision

According to our interviewee, when everyone were in the same office, they could easily go to each other’s table, communicate their ideas visually.

01. Receive sample

02. Find out issues

03. Discuss with developer

04. Make Revisions

Current - WFH

Remote Sample Revision

While working in different places or even different timezone, the designers needs to do extra annotation and documentation for clearer explanation.

01. Receive sample

02. Find out issues

03. Take pics and videos

04. Annotate the problem

05. Pin references

06. Note down dimensions

07. Schedule meeting

08. Make Revisions

"I feel it takes a longer time now to prepare what you want to talk about, that's for sure"

Mr.K, Sr footwear Desginer

Longer Discussions

2.

And why it's a problem

Problem 01

Sample Tangibility are Limited

Sometimes only a few team members have access to the sample, or they will only review it remotely based on the low quality video that factory sent.

This cause them missing design details and it’s hard for them to stay on the same page.

Problem 02

Mindset Difference Brings Inefficiency

Designers values creativity and user needs while developers focus on feasibibility and budget the most. There’s always compromise going on and extra explanation is needed to make their point through.

Problem 03

Harder to Build Trust

Withought the instant and natural feedback as in person does,any communication gap in the remote environment would be easily enlarged.

3D Workflow being more efficient nowadays

3.

And how is it hard to adapt

Current

2D Techpack Based Design

Different from other product disciplines, footwear designers design and iterate based on techpack because footwear 3D modeling needs too much extra effort and the techpack is clearer for developer and factory.

Trend

Design Review in 3D Basis

5 out of our 16 interviewees told us they tried several team review sessions in oculus as if they were meeting in person. By seeing the same model, their communication is more efficient.

However, this is hard to adapt 3D in their current workflow due to 1)budget,2)and sample developers still prefer techpack for clearer design details.

Efficiency = Quality + Time

Currently, either the work quality is sacrificed or the deadlilne would be delayed, overall efficiency is low.

In order to collaborate more efficiently, both footwear designers and developers needs:

Conclude Finding

01

Clear Interface for both roles to stay updated on project’s progress

02

Intuitive and accurate annotation tools

03

Organized and traceable revision history

04

Building Trust in the team through clearer communication

Our Goal

Make communication between designers and developer clearer so they build better trust and reduce work time.

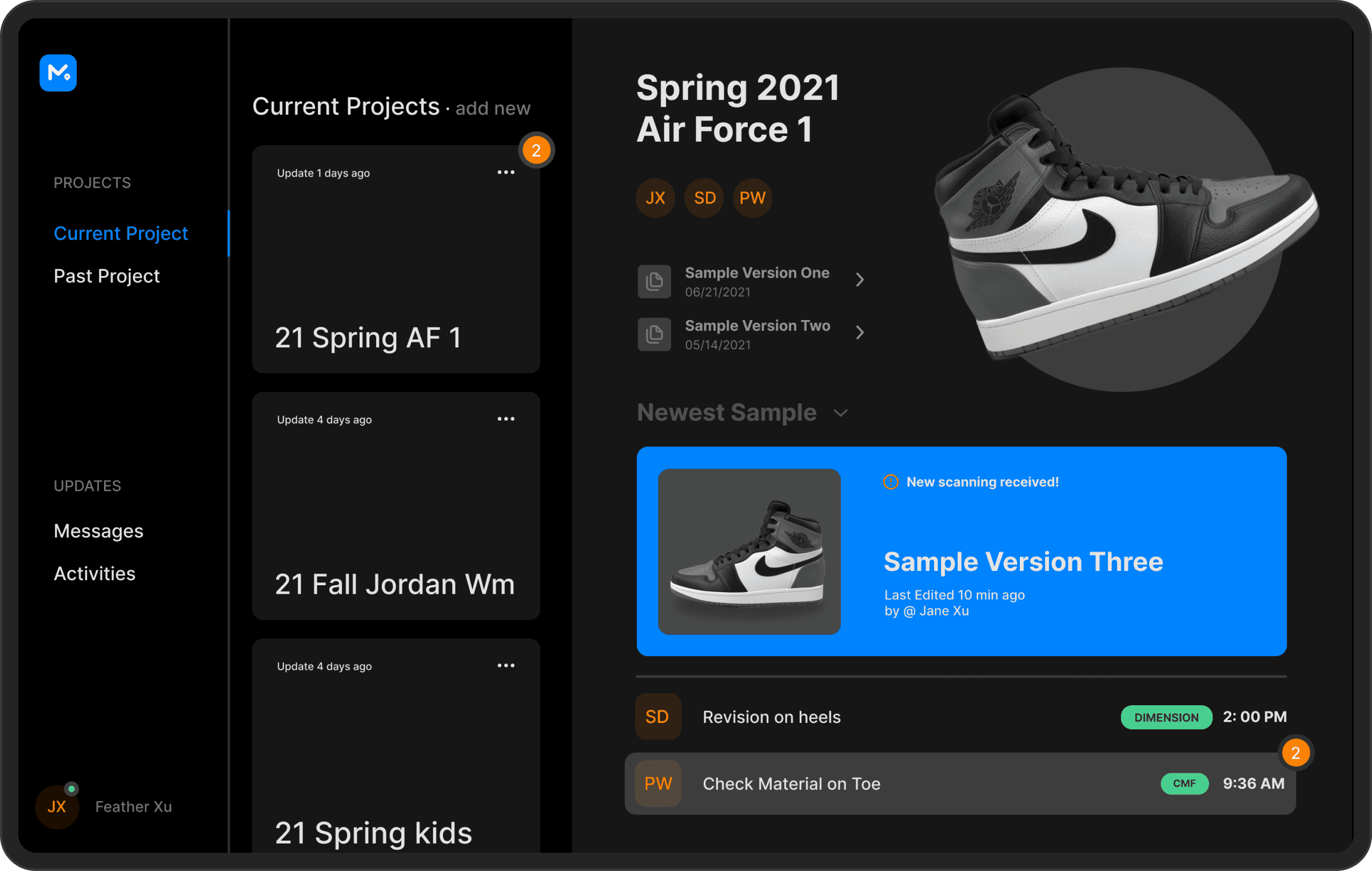

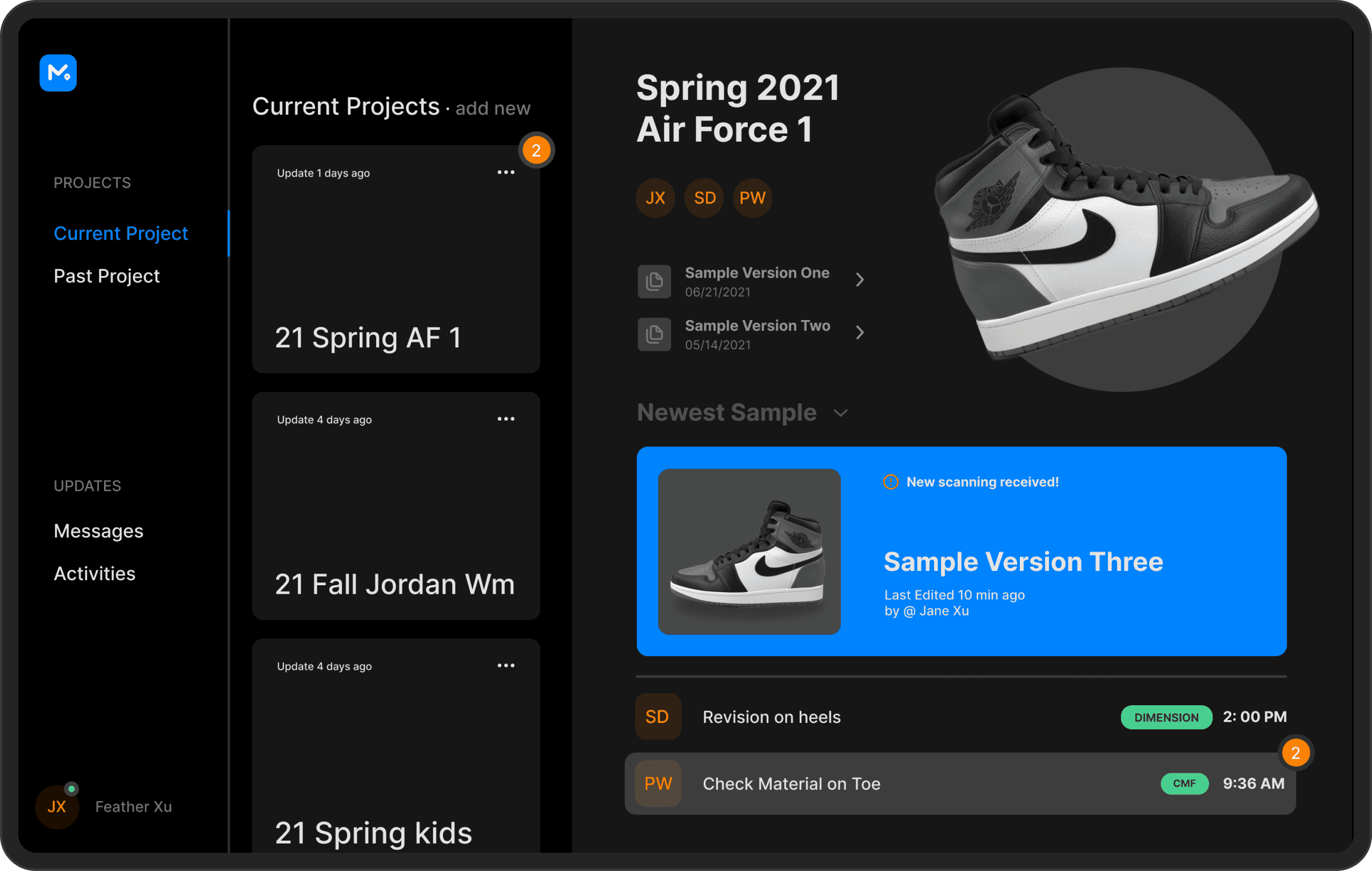

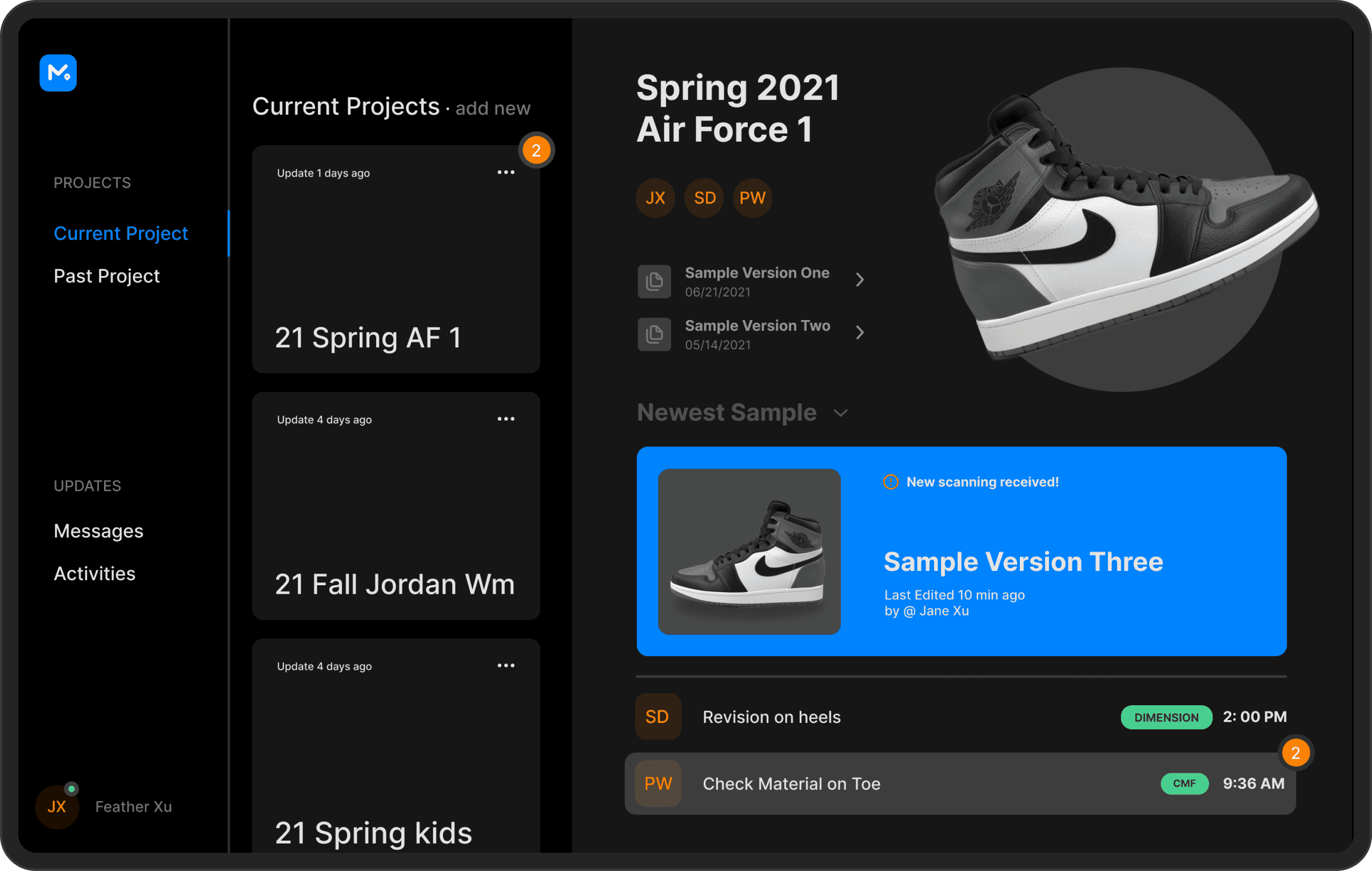

INTRODUCing OJO

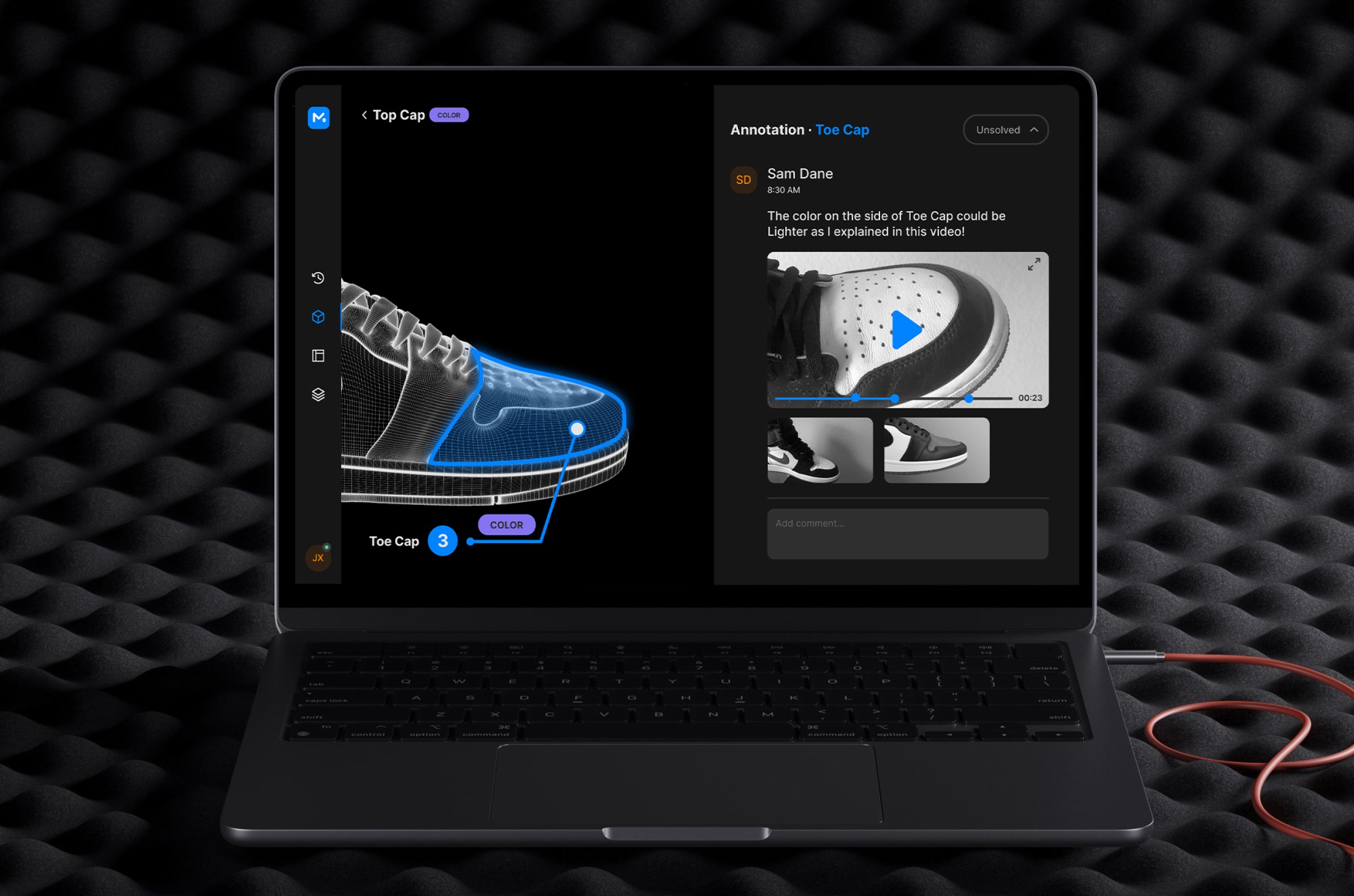

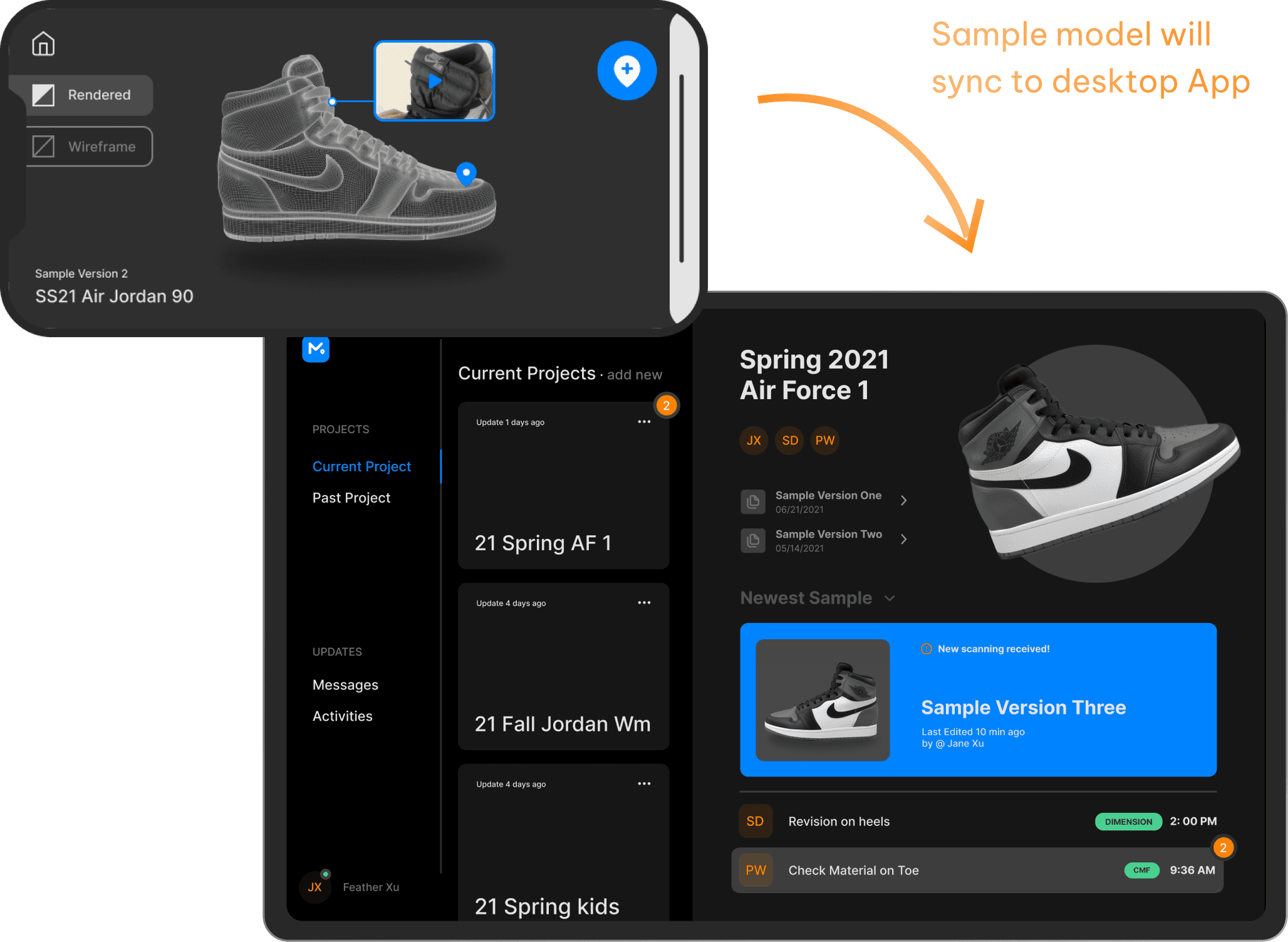

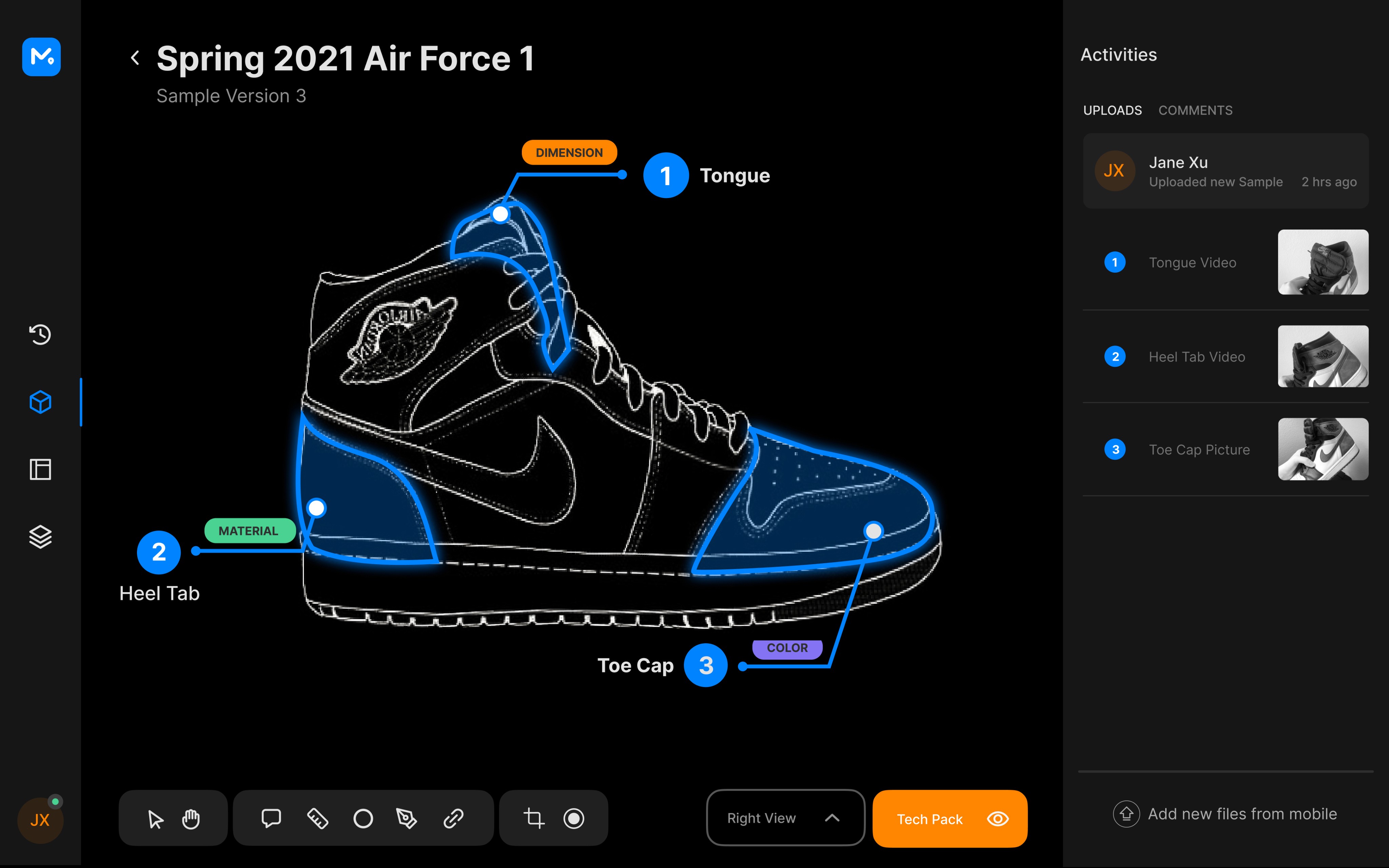

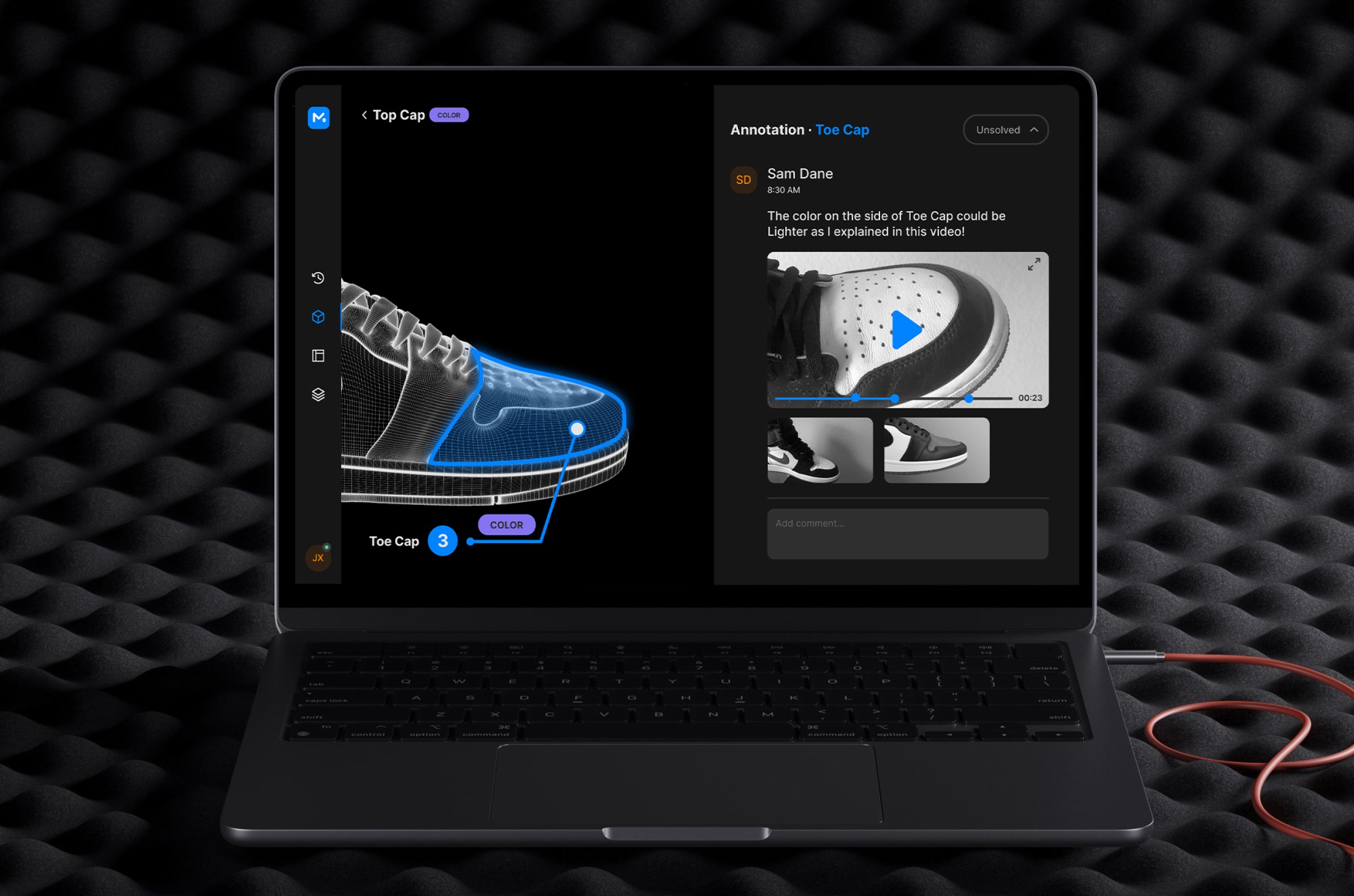

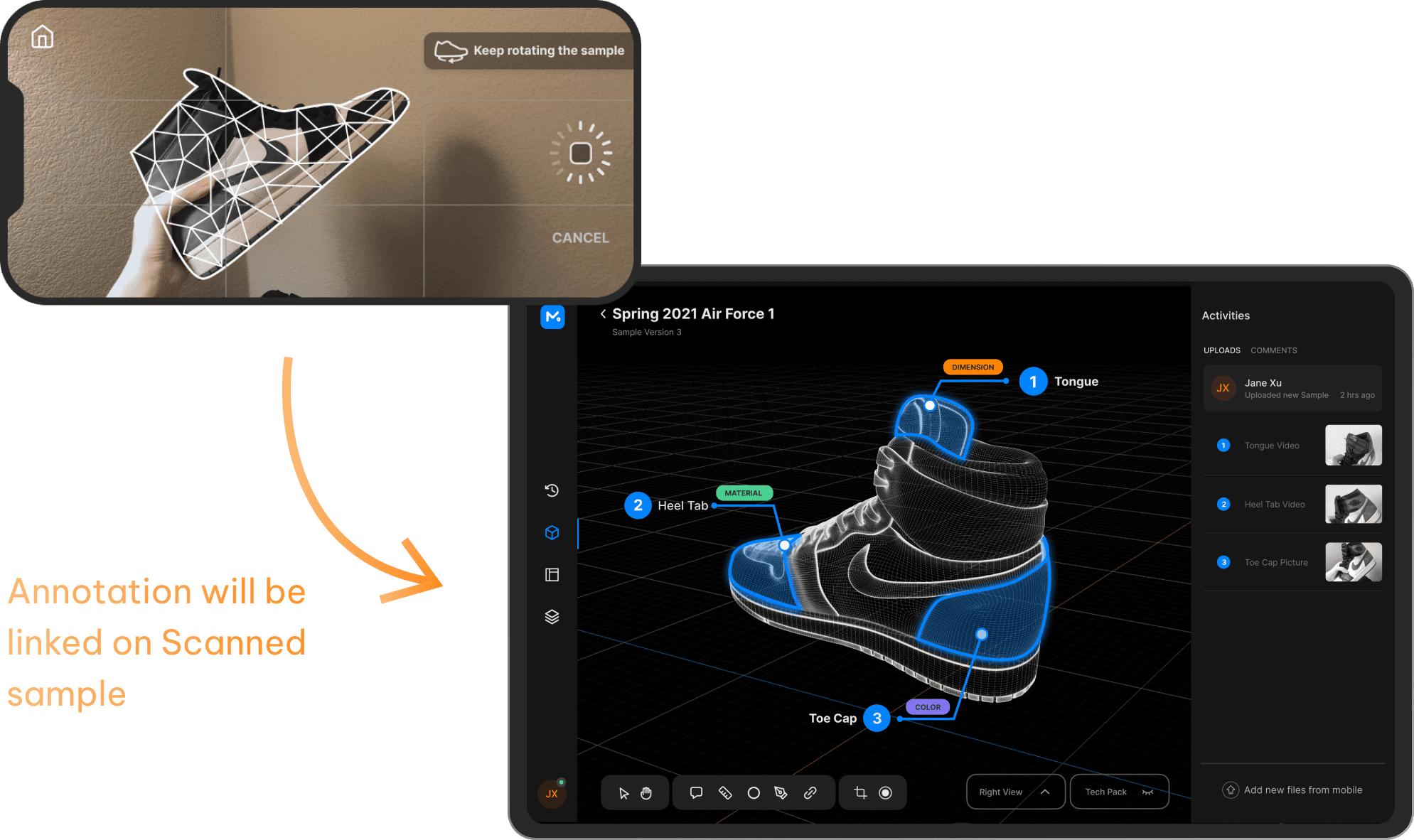

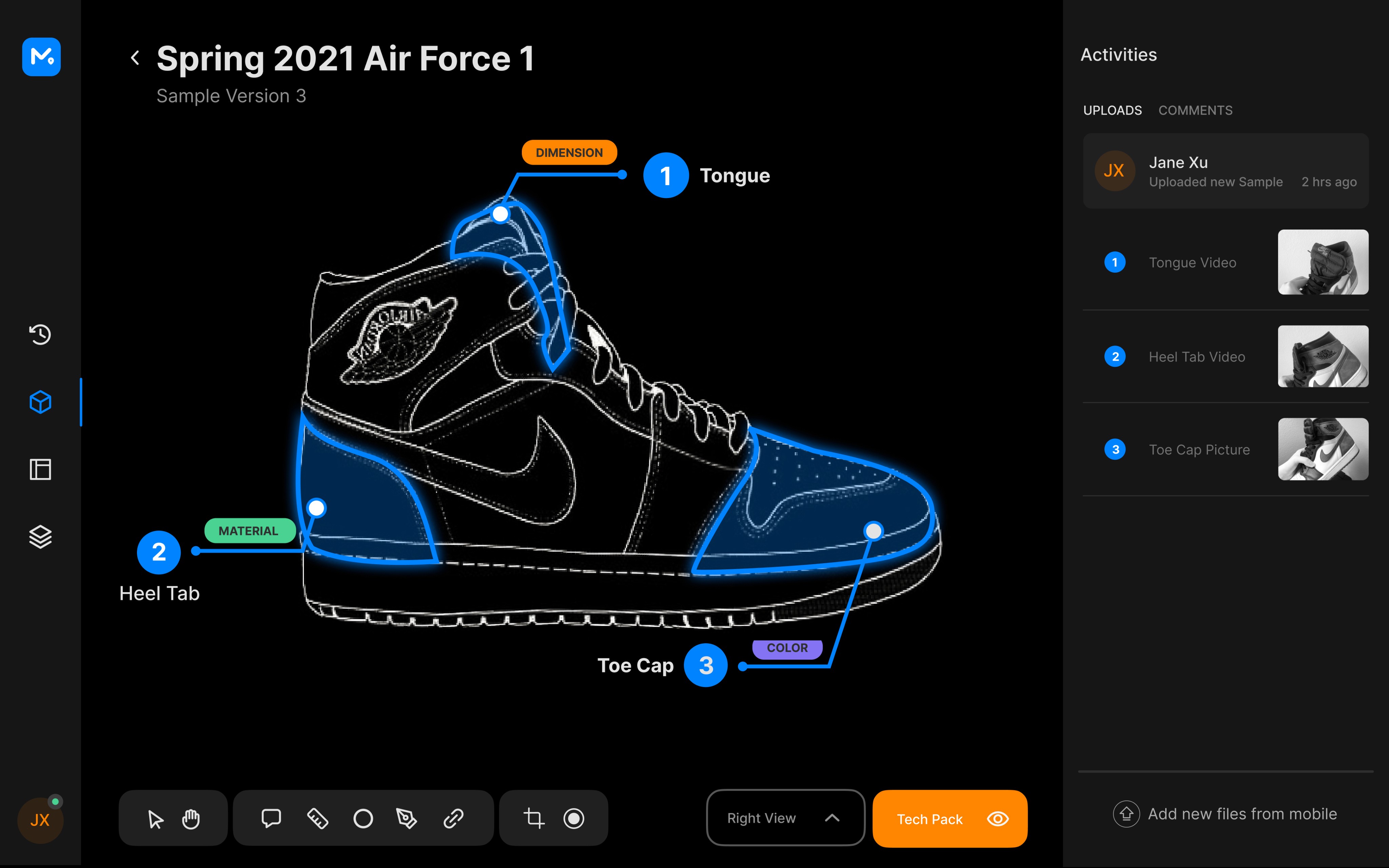

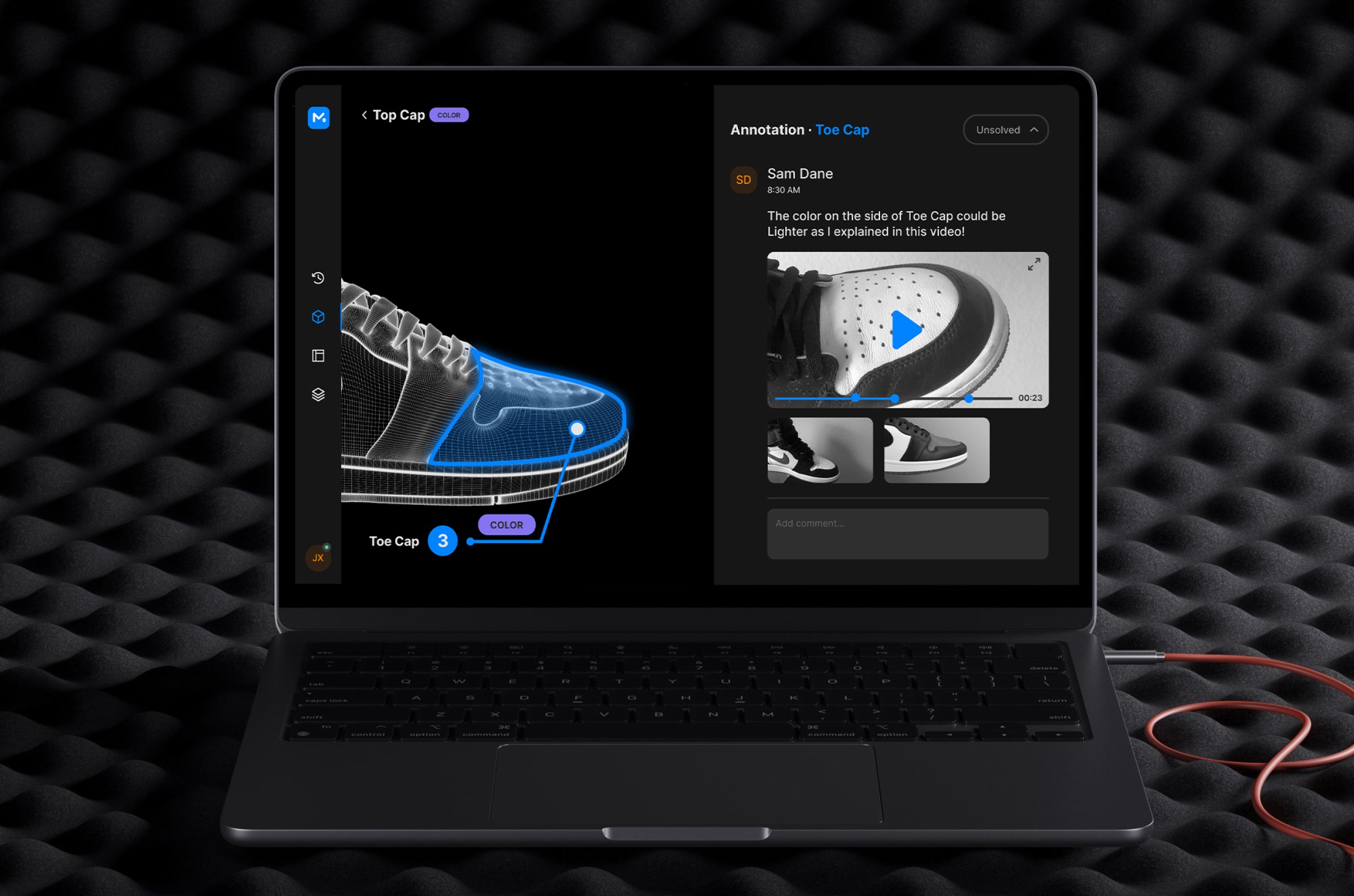

MarkO enables footwear designers to digitize and annotate physical samples with ease to empower better communication with engineers. Designers can 3D scan shoe prototypes and add virtual notes directly on the digital model using MarkO's intuitive tools.

Final Design

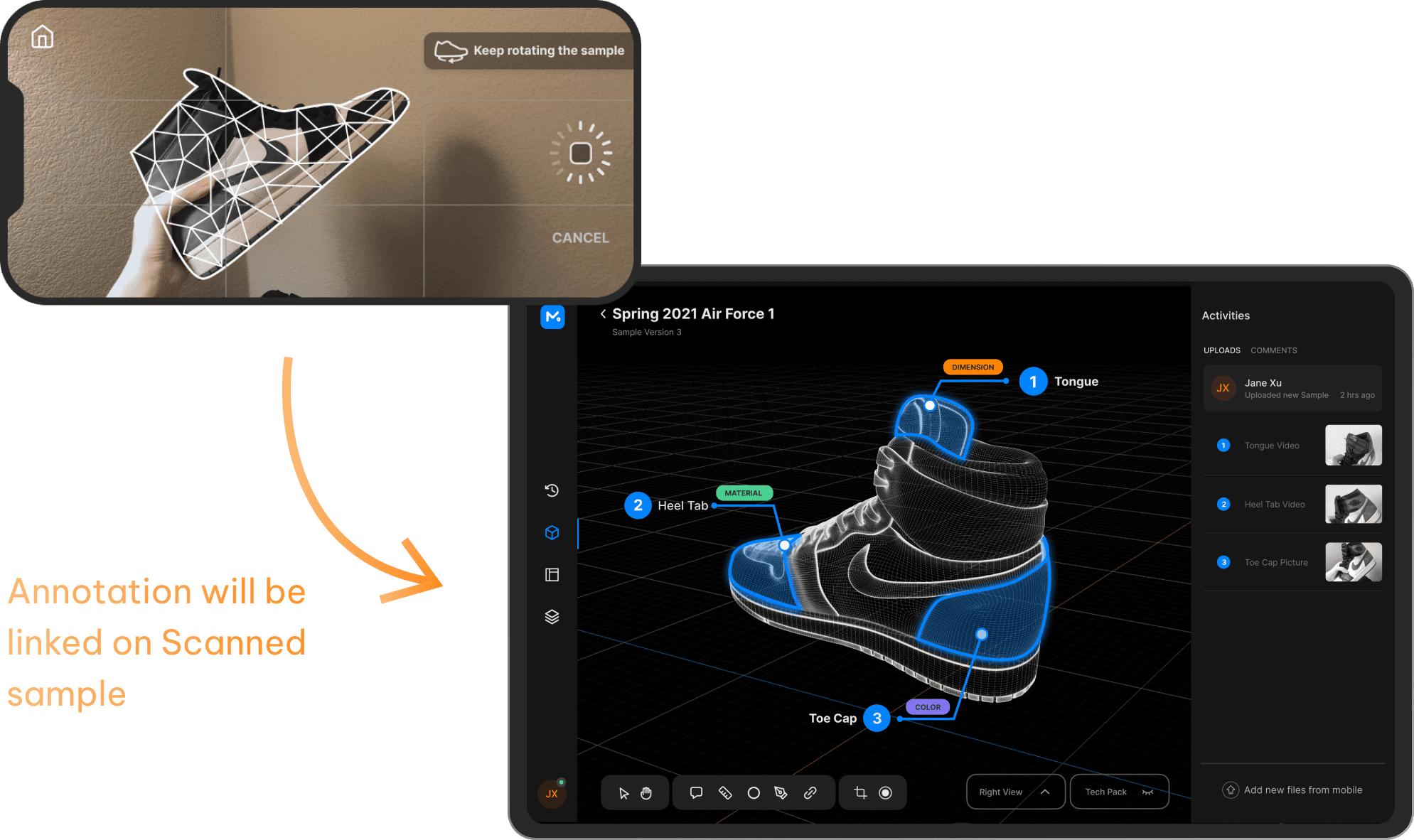

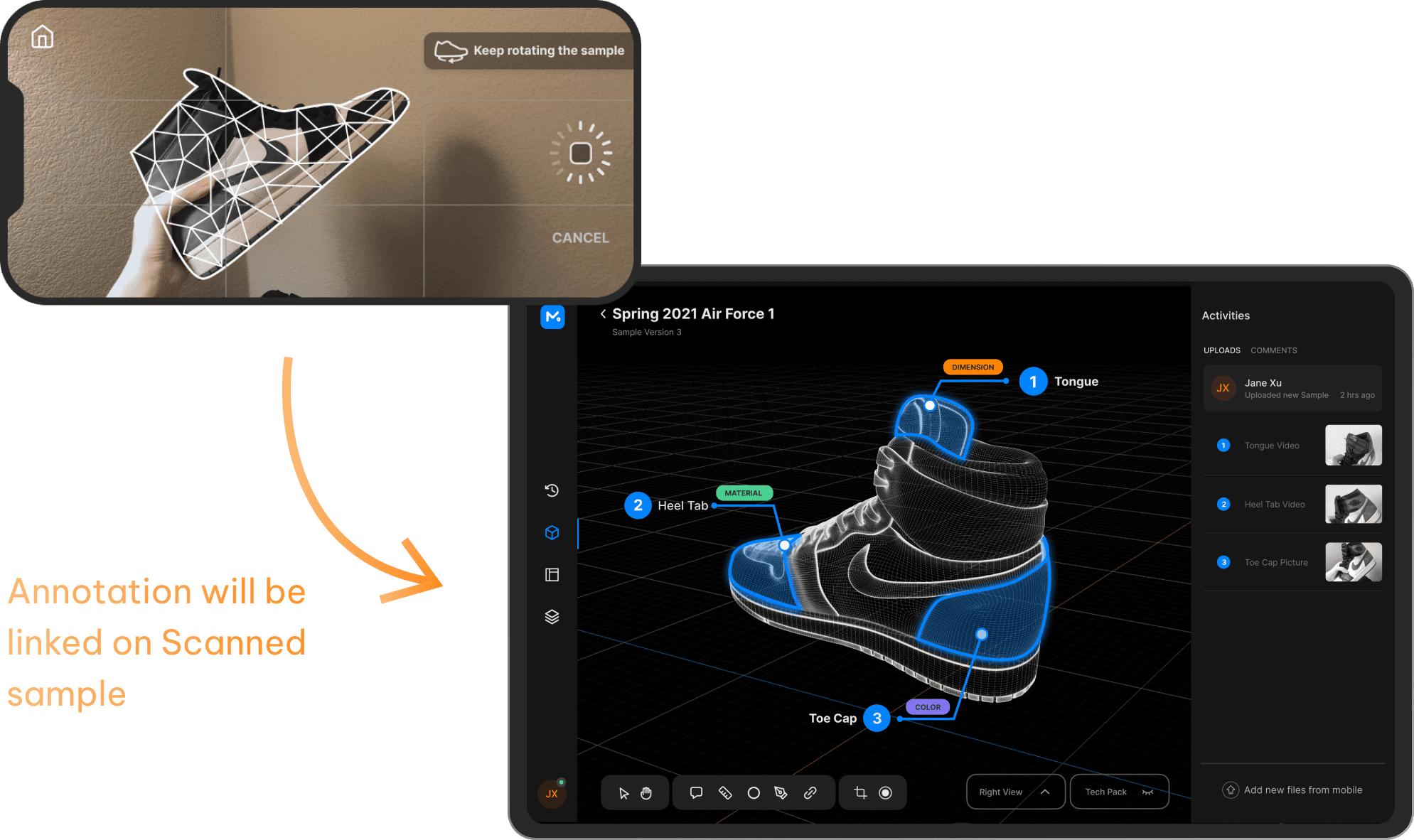

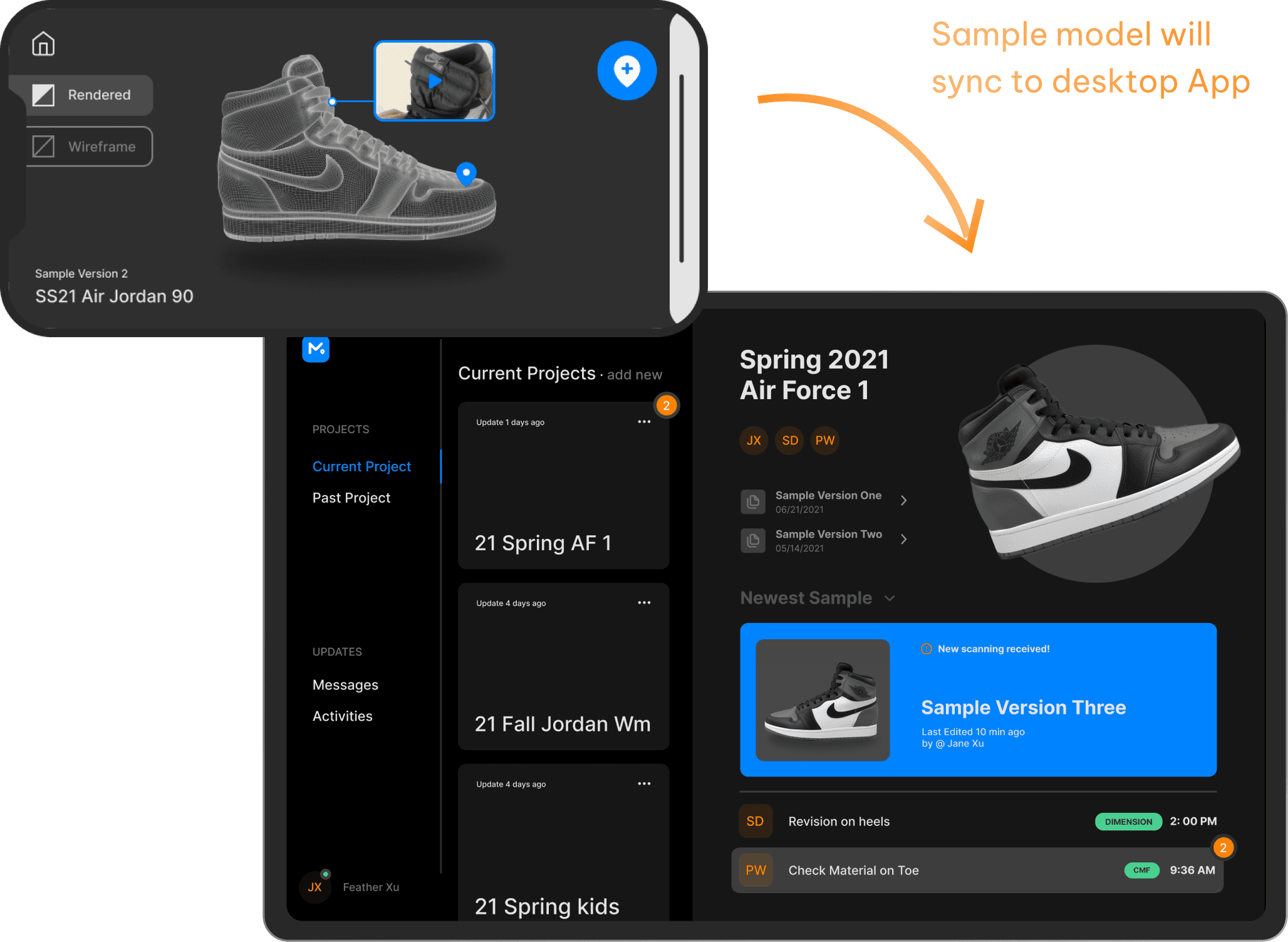

3D Scan & Navigation

Just by simply scanning the sample with user’s mobile phone, Marko can quickly convert it to a 3D model. All the annotations will be linked based on it so it’s clear for both designers and developers to follow up.

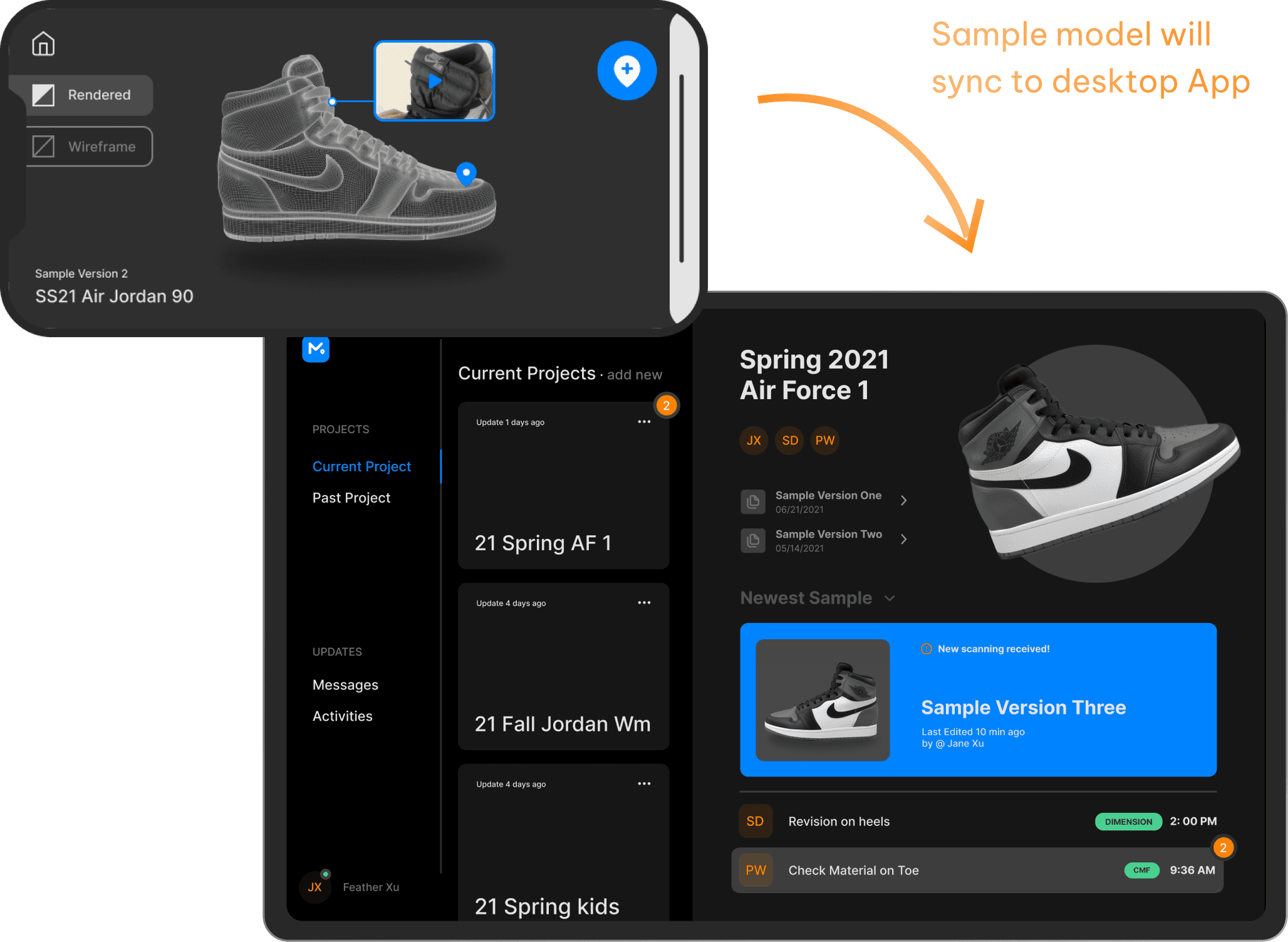

Apps are co-relate across platforms

Mobile and computer are also synchronized, any taken pictures and videos are all synchronized to the project on the computer side to minimize user’s effort needed.

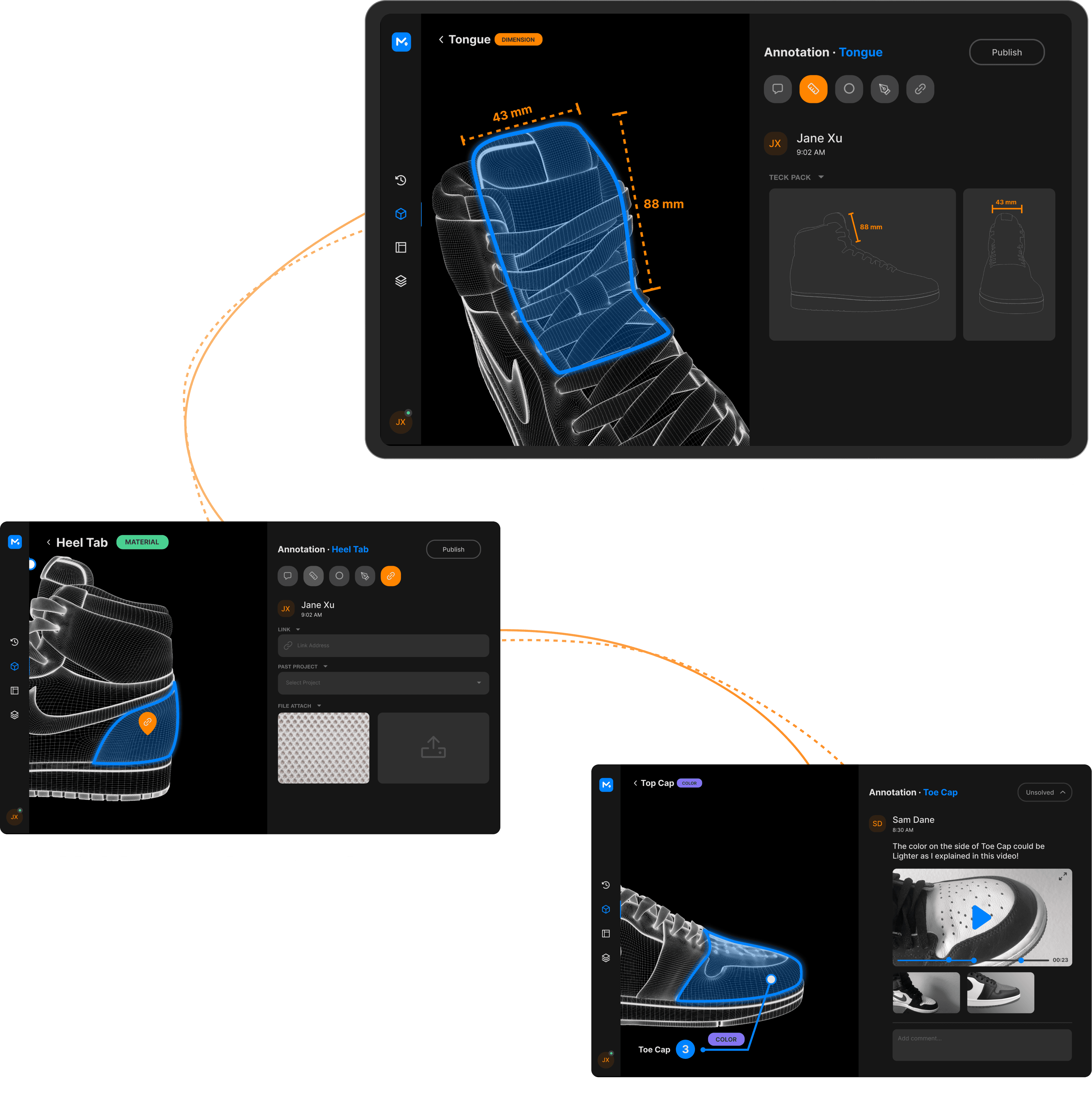

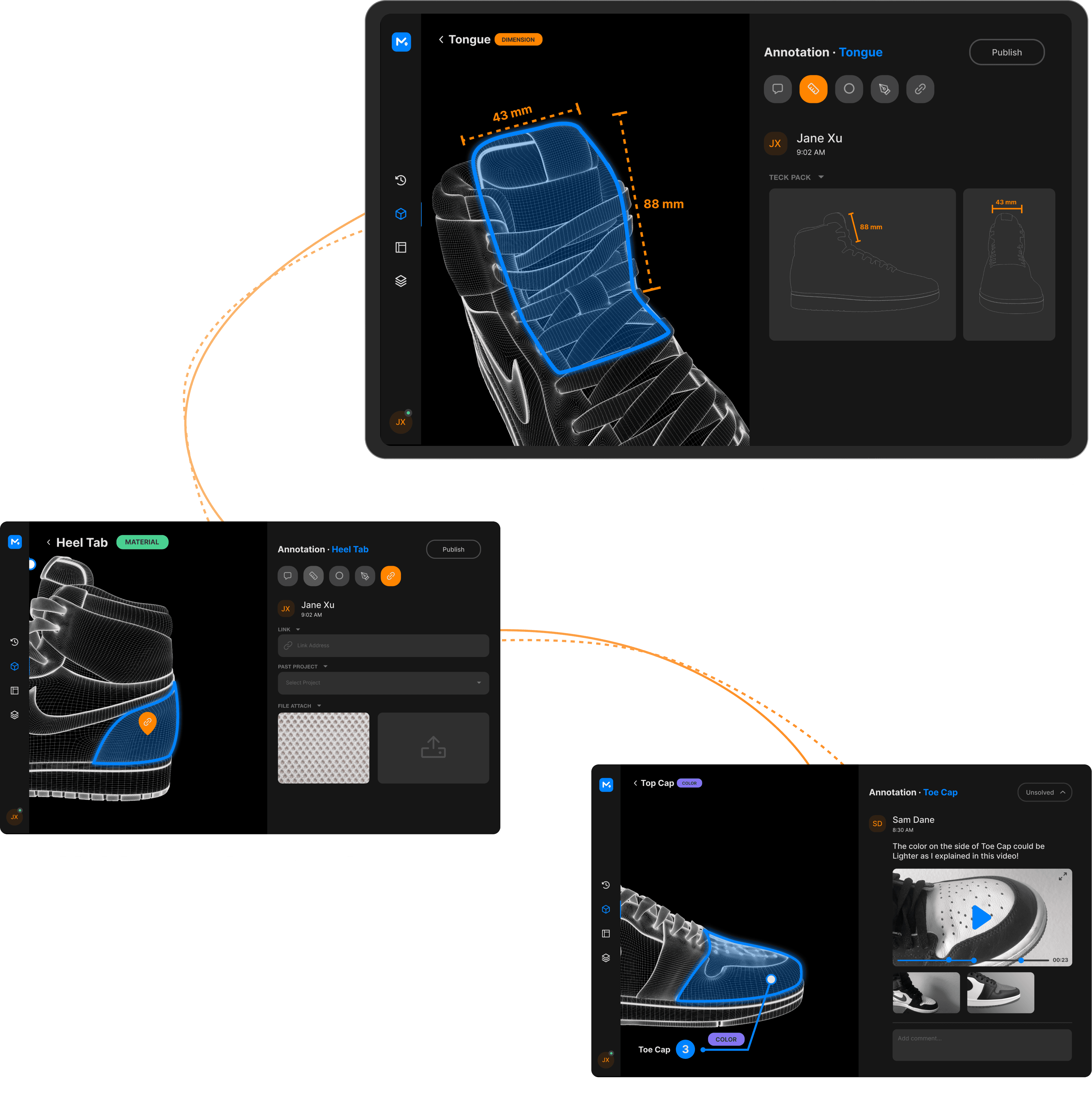

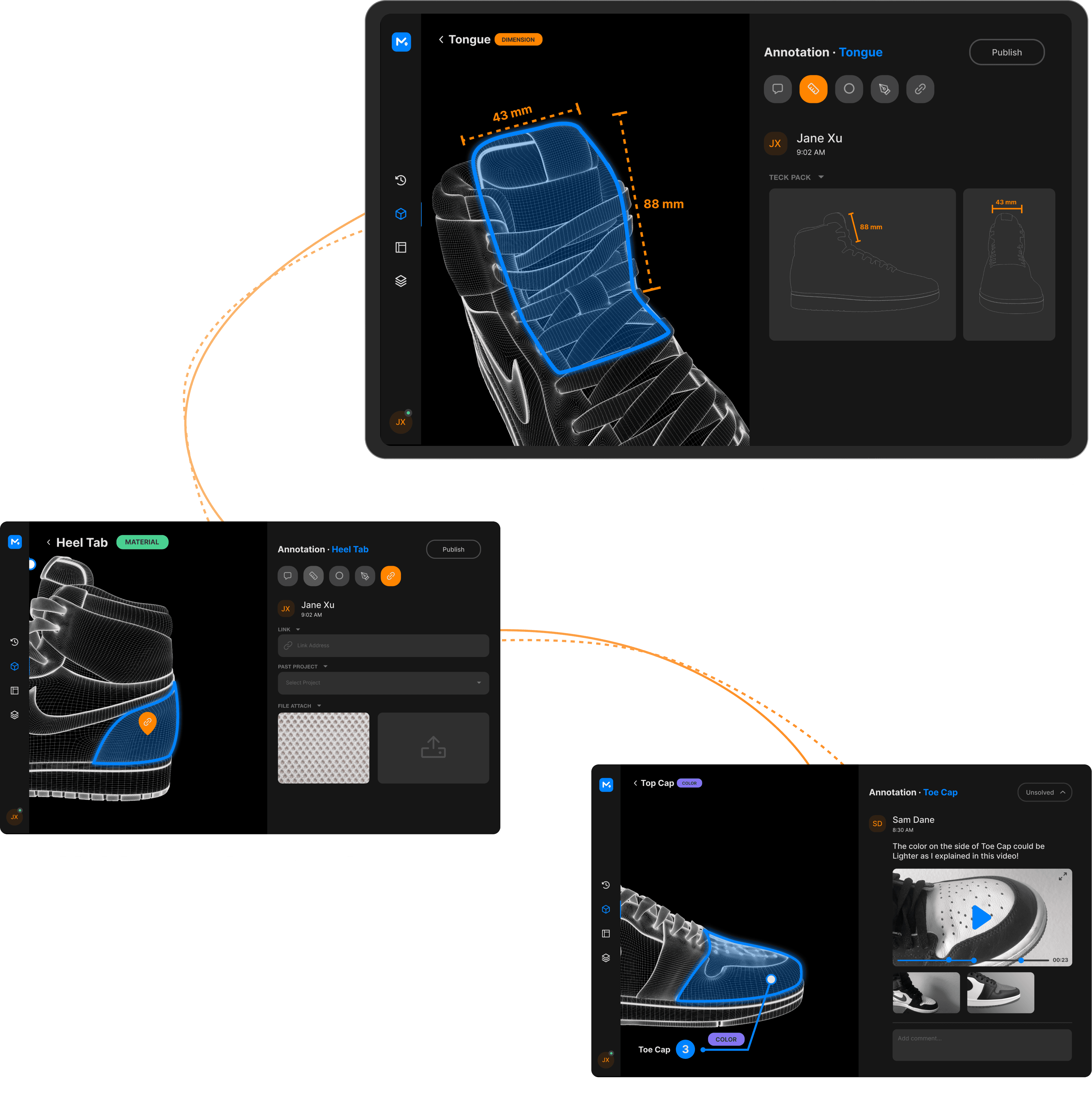

Accurate Annotation

Marko helps footwear designers to annotate on their sample based on their specific workflow.

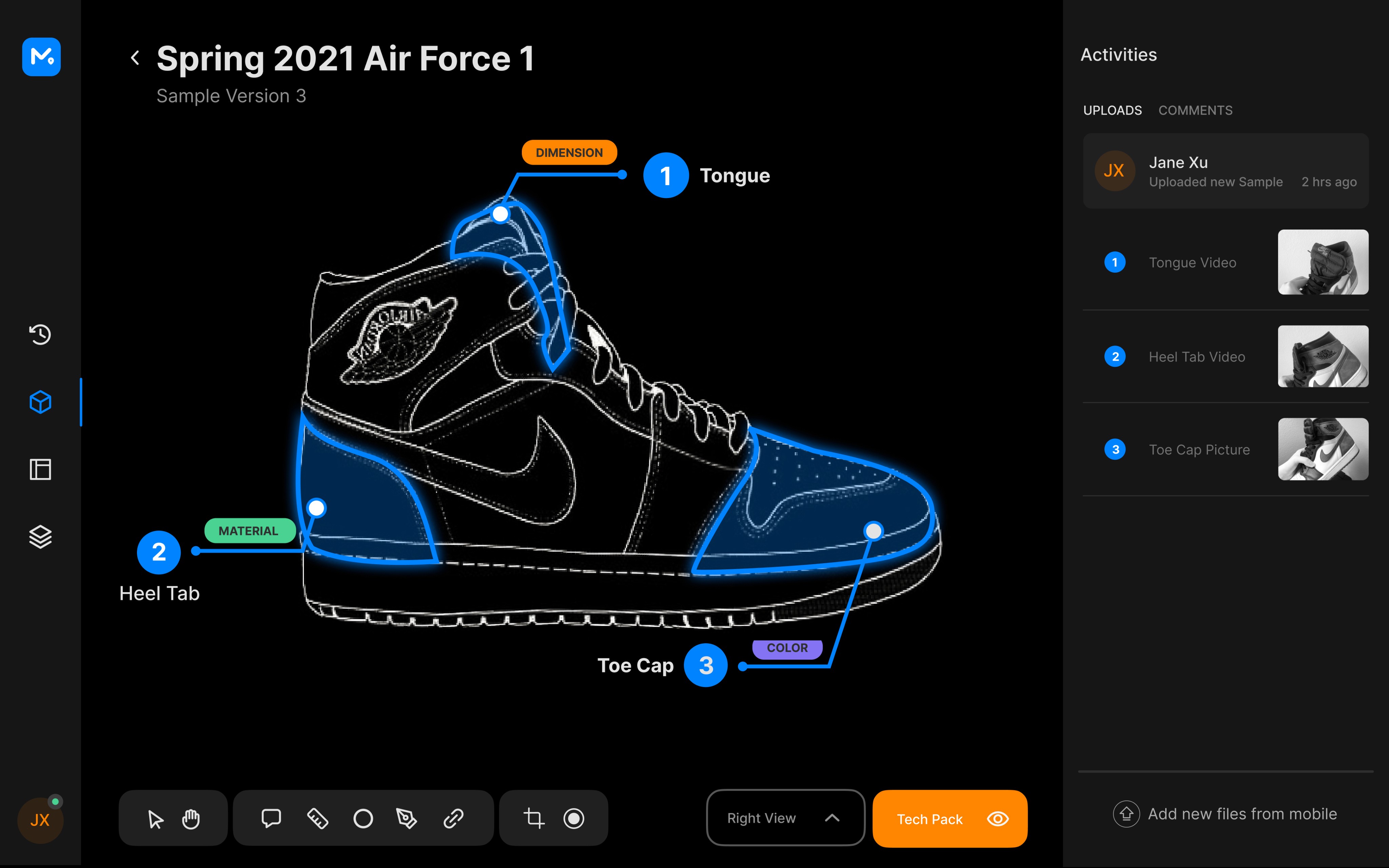

Apps are co-relate across platforms

Mobile and computer are also synchronized, any taken pictures and videos are all synchronized to the project on the computer side to minimize user’s effort needed.

Information are sync across 3D and Techpack

Tech pack and scanned 3D model are synchronized in MARKO. By turning on/off techpack, both designers and engineers can see the revisions clearly.

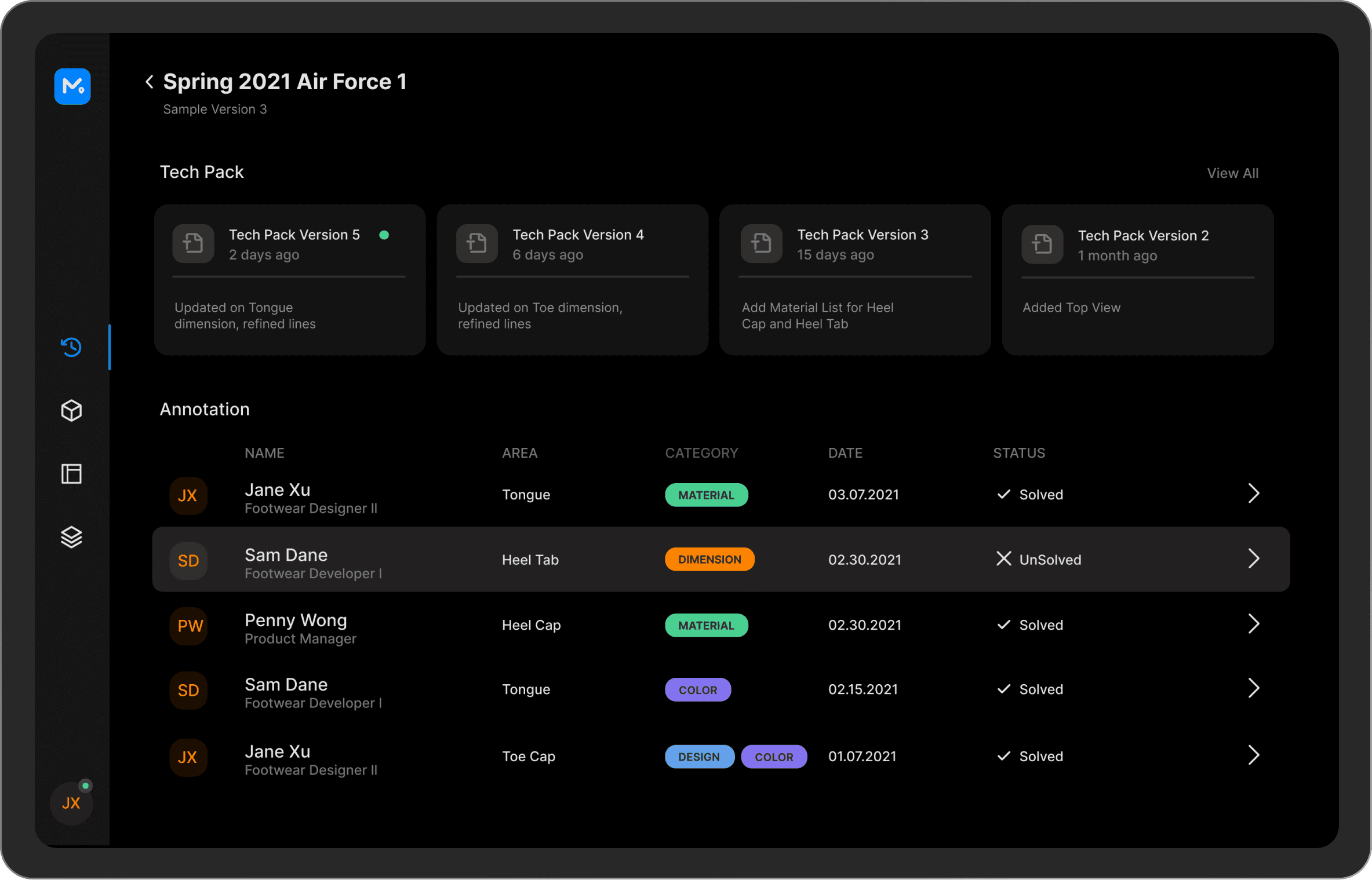

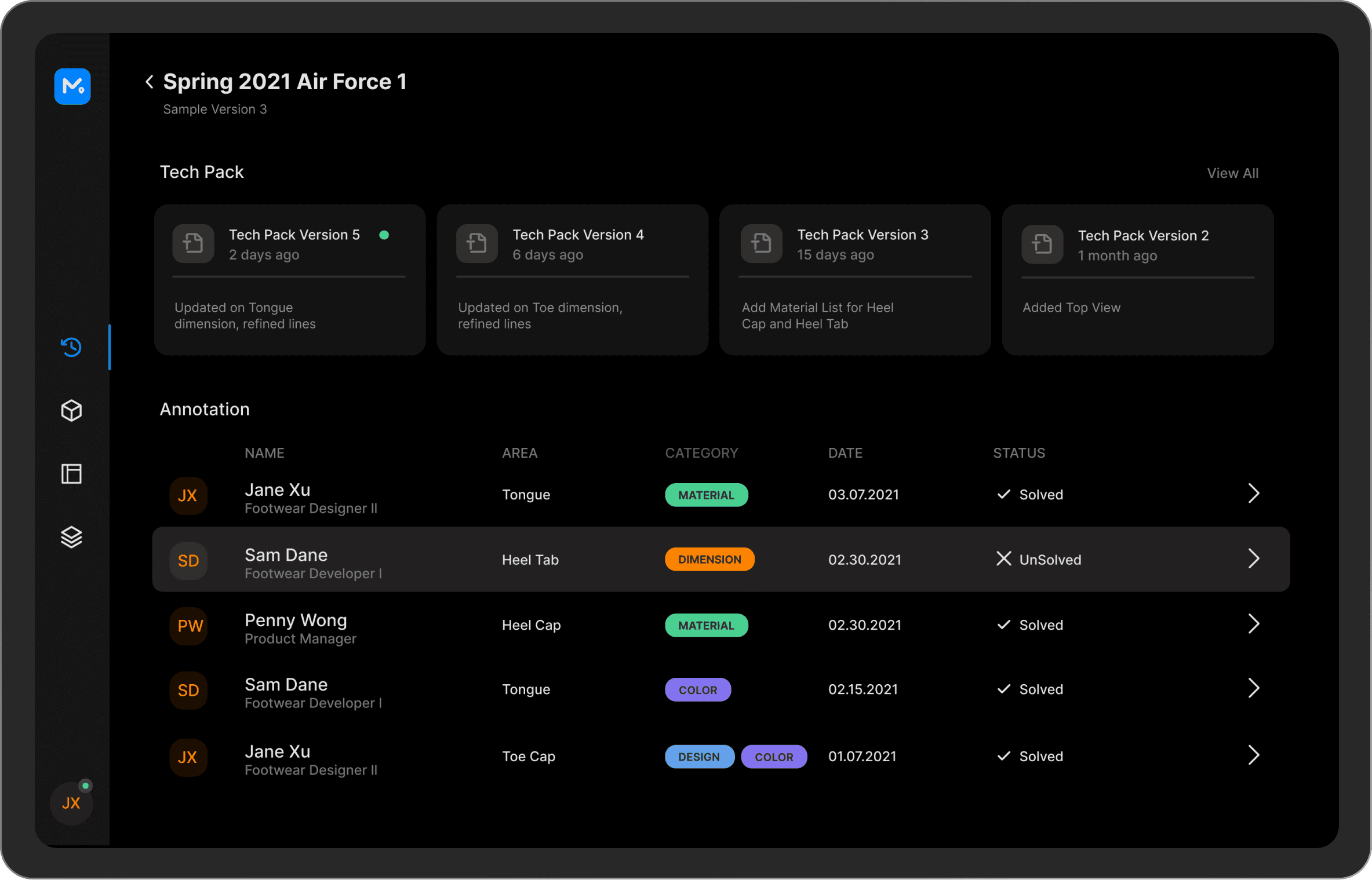

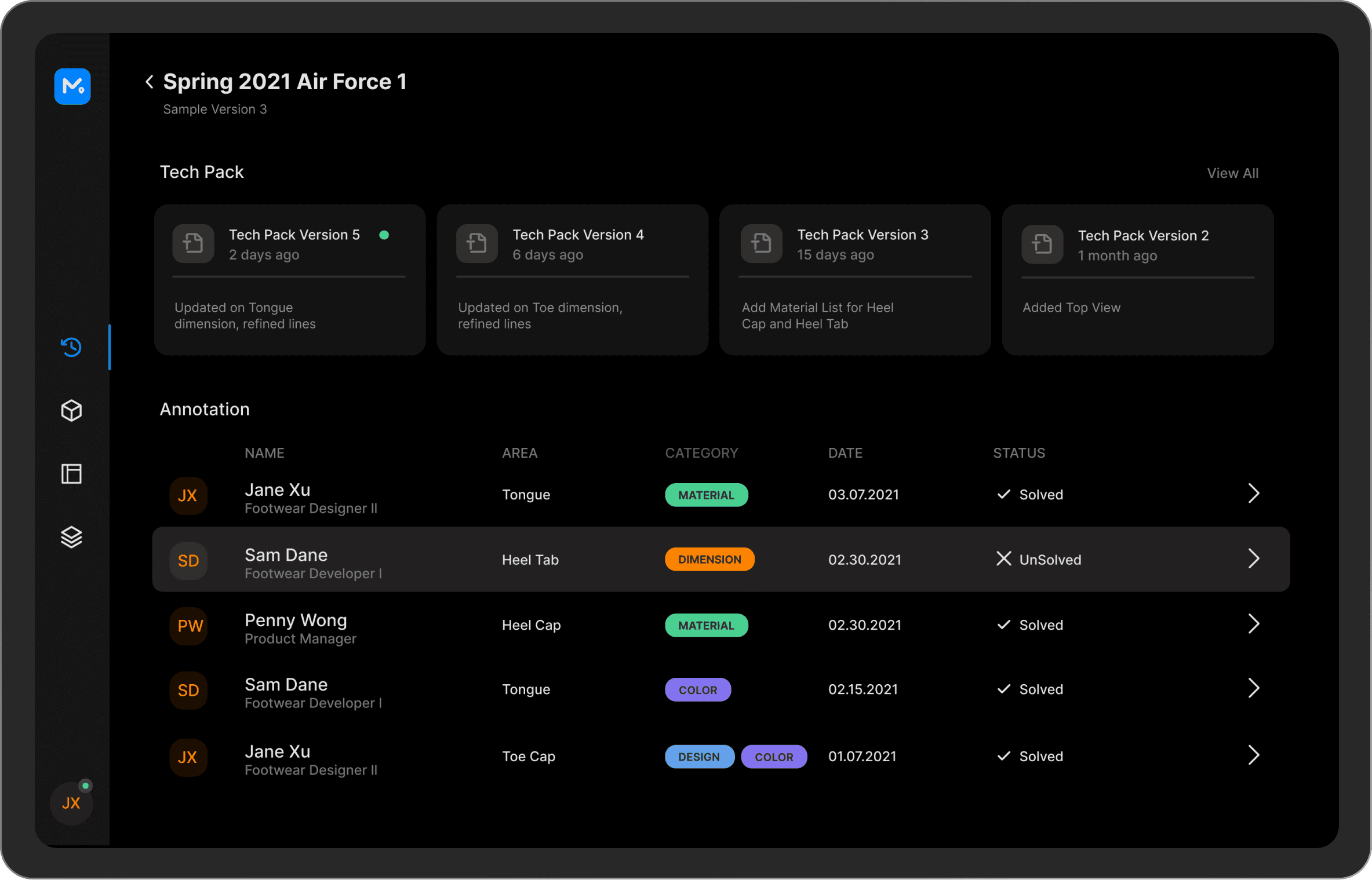

Revision History

Tech pack and scanned 3D model are synchronized in MARKO. By turning on/off techpack, both designers and engineers can see the revisions clearly.

Benefits of Marko

Creativity

Concise and understandable IA

Using the existing technology (and the technology under development) ---3D Lidar Scanner to create a navigation like a face-to-face review

Trustworthy

Significant reduction in userflow

Make full use of resources familiar to users for integration (such as techpack, one-click upload of photos, and automatic documentation.

Efficiency

Complementary Device

The mobile terminal focuses on taking pictures and video annotate, and the web version mainly focuses on rapid communication and feedback.

Reflection

What’s next

While Marko solves frustrations and improves productivity, it is also a feasible user solution with low learning costs. According to the development of technology, the system also has a lot of room for development. The future plan is to see how it could be quickly implemented and marketized based on the important level of the core business.

INTRODUCing OJO

MarkO enables footwear designers to digitize and annotate physical samples with ease to empower better communication with engineers. Designers can 3D scan shoe prototypes and add virtual notes directly on the digital model using MarkO's intuitive tools.

Final Design

3D Scan & Navigation

Just by simply scanning the sample with user’s mobile phone, Marko can quickly convert it to a 3D model. All the annotations will be linked based on it so it’s clear for both designers and developers to follow up.

Apps are co-relate across platforms

Mobile and computer are also synchronized, any taken pictures and videos are all synchronized to the project on the computer side to minimize user’s effort needed.

Accurate Annotation

Marko helps footwear designers to annotate on their sample based on their specific workflow.

Apps are co-relate across platforms

Mobile and computer are also synchronized, any taken pictures and videos are all synchronized to the project on the computer side to minimize user’s effort needed.

Information are sync across 3D and Techpack

Tech pack and scanned 3D model are synchronized in MARKO. By turning on/off techpack, both designers and engineers can see the revisions clearly.

Revision History

Tech pack and scanned 3D model are synchronized in MARKO. By turning on/off techpack, both designers and engineers can see the revisions clearly.

Benefits of Marko

Creativity

Concise and understandable IA

Using the existing technology (and the technology under development) ---3D Lidar Scanner to create a navigation like a face-to-face review

Trustworthy

Significant reduction in userflow

Make full use of resources familiar to users for integration (such as techpack, one-click upload of photos, and automatic documentation.

Efficiency

Complementary Device

The mobile terminal focuses on taking pictures and video annotate, and the web version mainly focuses on rapid communication and feedback.

Reflection

What’s next

While Marko solves frustrations and improves productivity, it is also a feasible user solution with low learning costs. According to the development of technology, the system also has a lot of room for development. The future plan is to see how it could be quickly implemented and marketized based on the important level of the core business.

INTRODUCing OJO

MarkO enables footwear designers to digitize and annotate physical samples with ease to empower better communication with engineers. Designers can 3D scan shoe prototypes and add virtual notes directly on the digital model using MarkO's intuitive tools.

Final Design

3D Scan & Navigation

Just by simply scanning the sample with user’s mobile phone, Marko can quickly convert it to a 3D model. All the annotations will be linked based on it so it’s clear for both designers and developers to follow up.

Apps are co-relate across platforms

Mobile and computer are also synchronized, any taken pictures and videos are all synchronized to the project on the computer side to minimize user’s effort needed.

Accurate Annotation

Marko helps footwear designers to annotate on their sample based on their specific workflow.

Apps are co-relate across platforms

Mobile and computer are also synchronized, any taken pictures and videos are all synchronized to the project on the computer side to minimize user’s effort needed.

Information are sync across 3D and Techpack

Tech pack and scanned 3D model are synchronized in MARKO. By turning on/off techpack, both designers and engineers can see the revisions clearly.

Revision History

Tech pack and scanned 3D model are synchronized in MARKO. By turning on/off techpack, both designers and engineers can see the revisions clearly.

Benefits of Marko

Creativity

Concise and understandable IA

Using the existing technology (and the technology under development) ---3D Lidar Scanner to create a navigation like a face-to-face review

Trustworthy

Significant reduction in userflow

Make full use of resources familiar to users for integration (such as techpack, one-click upload of photos, and automatic documentation.

Efficiency

Complementary Device

The mobile terminal focuses on taking pictures and video annotate, and the web version mainly focuses on rapid communication and feedback.

Reflection

What’s next

While Marko solves frustrations and improves productivity, it is also a feasible user solution with low learning costs. According to the development of technology, the system also has a lot of room for development. The future plan is to see how it could be quickly implemented and marketized based on the important level of the core business.